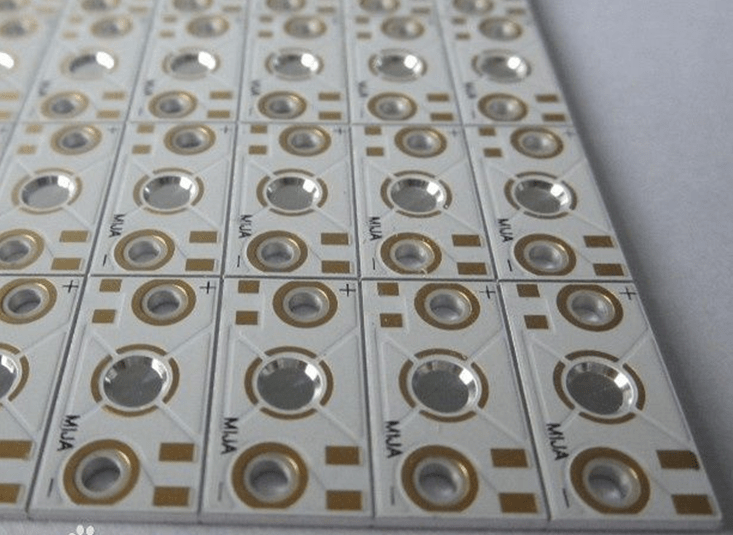

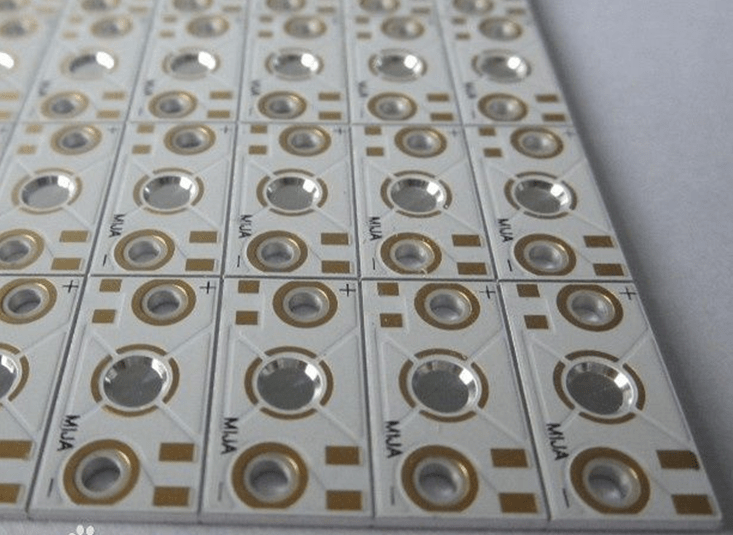

Metal Core Printed Circuit Boards (MCPCBs) offer several advantages over traditional FR-4 PCBs, which have a fiberglass substrate with a copper layer. The key advantages of MCPCBs include:

- Thermal Conductivity: The most significant advantage of MCPCBs is their high thermal conductivity. They are designed to dissipate heat efficiently, making them ideal for applications that generate a significant amount of heat, such as power electronics, LED lighting, and high-power RF devices. The metal core acts as a heat sink, effectively conducting and dissipating heat away from sensitive components, thus preventing overheating and extending the lifespan of electronic components.

- Improved Heat Management: MCPCBs allow for more efficient and effective heat management without the need for additional heat sinks or thermal vias. This can lead to smaller and more compact designs, reducing the overall size of the electronic device.

- Higher Power Handling: Because of their superior thermal properties, MCPCBs can handle higher power levels and current loads. This makes them suitable for applications that require high-power circuitry and better thermal performance.

- Enhanced Reliability: With improved heat dissipation, MCPCBs can help increase the reliability and operational lifespan of electronic components. Lower operating temperatures can reduce the risk of component failure and degradation over time.

- Improved Electrical Performance: The metal core in MCPCBs also provides a good grounding effect, reducing electromagnetic interference (EMI) and improving signal integrity in high-frequency applications. This is particularly important in RF and microwave designs.

- Structural Stability: Metal cores provide additional structural stability to the PCB, making them more resistant to mechanical stresses, vibrations, and shock. This is especially beneficial in applications where the PCB may be subjected to physical stress.

- Weight Reduction: MCPCBs are often lighter than their FR-4 counterparts, which can be advantageous in applications where weight is a critical factor, such as in aerospace and automotive industries.

- Design Flexibility: MCPCBs can be designed with a variety of metal core materials, such as aluminum, copper, or steel, allowing designers to select the most suitable material for their specific application.

- Environmentally Friendly: MCPCBs are often considered more eco-friendly as they are fully recyclable, and the materials used are non-toxic.

- Cost-Efficiency: While MCPCBs can be more expensive than traditional FR-4 PCBs, their benefits in terms of heat management and reliability can offset the initial cost by reducing the need for additional cooling solutions and lowering the risk of component failure.

It’s important to note that the choice between Metal Core PCBs and traditional PCBs depends on the specific requirements of the application, and not all applications require the advantages offered by MCPCBs. Designers should carefully evaluate their project’s needs before selecting the appropriate PCB type.