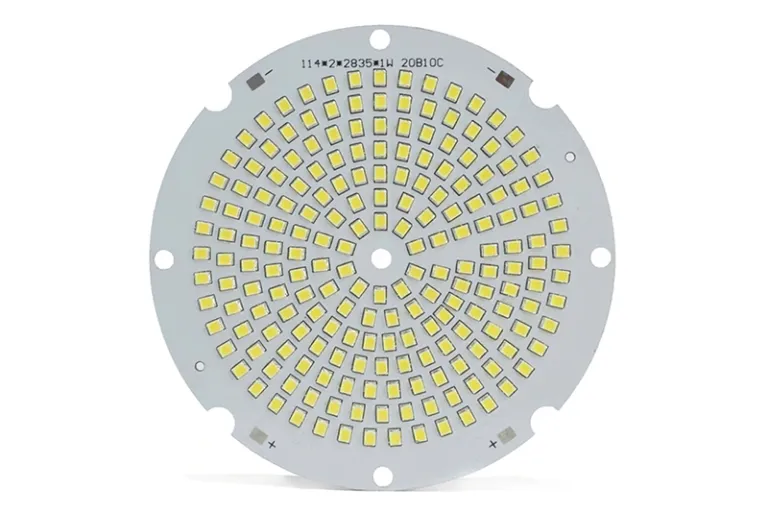

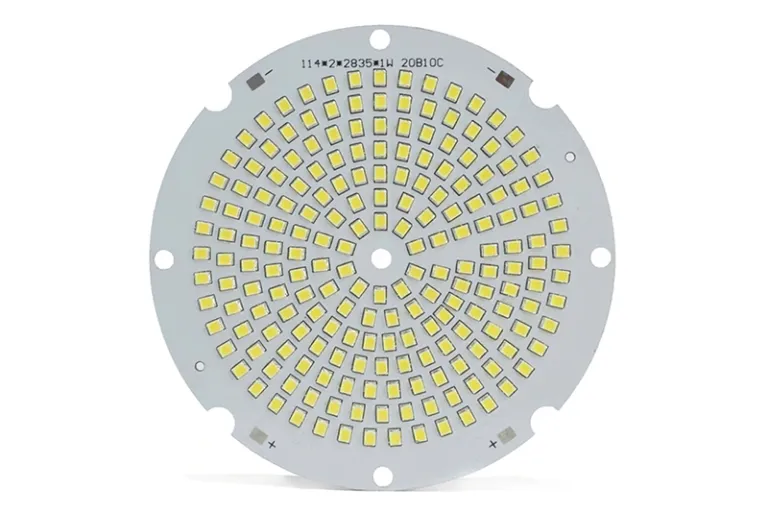

Aluminum printed circuit board has excellent electrical performance, heat dissipation, electromagnetic shielding, high dielectric strength and bending resistance. It is widely used in many industries, such as high-power LED lighting, power supply, TV backlight, automobile, computer, air conditioning frequency conversion module, avionics, telecommunications, health care, audio, etc. Even the most commonly used mobile phone camera, aluminum PCB has become an important part of mobile phone.

Aluminum PCB has been popular since it was first used in power amplifier hybrid IC (integrated circuit). In recent years, especially due to the power of LED industry, the application and development trend of aluminum PCB are increasingly extensive. Therefore, it is necessary to understand some important functions of aluminum PCB so that they can be better used in your product or industry.

1. Copper foil layer

Aluminum clad copper clad laminate has the same copper foil layer as ordinary copper clad laminate, and the circuit layer needs larger current carrying capacity, which is why relatively thick copper circuit should be selected, with the thickness between 1oz and 10oz. The back of the copper foil must be chemically oxidized, while the surface should be galvanized, and brass plated to improve the peel strength.

2. Dielectric layer

The dielectric layer is composed of a layer of thermal conductive dielectric material with low thermal conductivity, which is the core technology of aluminum copper clad laminate. It has excellent thermal aging resistance and can withstand mechanical and thermal stresses.

3. Aluminum base

Aluminum base is actually aluminum matrix material, which is the supporting component of aluminum base. It requires high thermal conductivity and is suitable for general mechanical manufacturing, such as drilling, punching and cutting.

4. Aluminum based membrane

Aluminum based film can protect aluminum surface from scratch and corrosive agent. Membrane can be divided into ordinary and high temperature resistant. The latter type can meet the requirements of HASL (hot air solder leveling) surface finish.