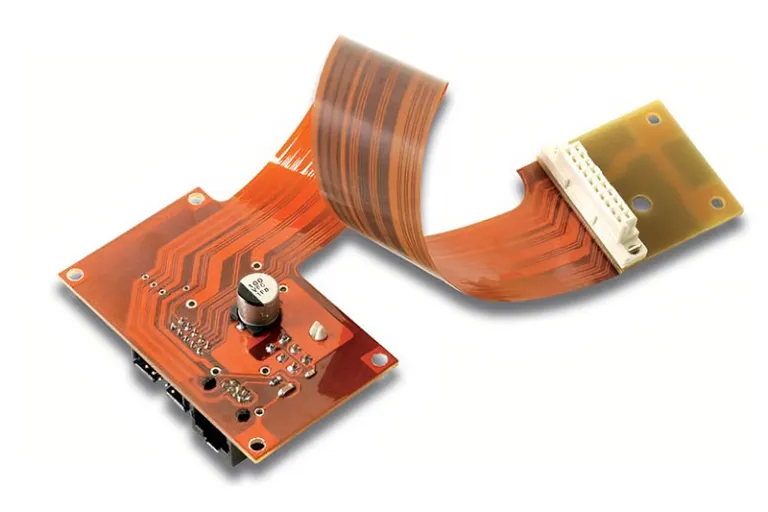

Rigid flex PCBs are revolutionizing the world of electronics with their unmatched flexibility and durability. In this article, we will explore the advantages of these innovative circuit boards and how they are unlocking new possibilities for various industries.

With the ability to bend, twist, and fold without compromising functionality, rigid-flex PCBs offer a level of design freedom that traditional boards can’t match. This makes them ideal for applications that require compact and lightweight solutions, such as wearable devices, aerospace systems, and medical equipment.

One of the key advantages of rigid-flex PCBs is their ability to reduce the need for interconnects, resulting in improved reliability and reduced assembly time and cost. Additionally, their three-dimensional integration capabilities allow for more efficient use of available space, leading to smaller and more powerful devices.

Moreover, their flexibility allows for easier installation and maintenance in challenging environments, making them highly suitable for rugged applications. Whether it’s in harsh industrial settings or extreme weather conditions, rigid-flex PCBs can handle it all.

Join us as we dive deeper into the advantages of rigid-flex PCBs and discover how these versatile circuit boards are shaping the future of electronics.

Rigid flex PCBs offer several advantages over traditional circuit boards. Firstly, their ability to bend, twist, and fold without compromising functionality opens up a whole new world of design possibilities. This makes them ideal for applications that require compact and lightweight solutions, such as wearable devices, aerospace systems, and medical equipment. With rigid-flex PCBs, designers can create sleek and ergonomic products that were previously unimaginable.

Secondly, rigid-flex PCBs reduce the need for interconnects, resulting in improved reliability and reduced assembly time and cost. Unlike traditional PCBs that require multiple connectors and cables to connect different boards, rigid-flex PCBs integrate all the necessary components into a single structure. This eliminates the risk of loose connections and reduces the chances of failure due to faulty interconnects. The simplified assembly process also saves time and resources, making rigid-flex PCBs a cost-effective solution.

Furthermore, rigid-flex PCBs offer three-dimensional integration capabilities, allowing for more efficient use of available space. By stacking multiple layers of flexible and rigid substrates, designers can maximize the functionality and performance of their electronic devices. This compact design enables the creation of smaller and more powerful devices, which is crucial in today’s fast-paced technological landscape.

The advantages of rigid-flex PCBs make them highly versatile and suitable for a wide range of applications. One prominent area where these circuit boards excel is wearable technology. From fitness trackers to smartwatches, rigid-flex PCBs enable the creation of wearable devices that are comfortable to wear and can withstand constant movement and bending. The flexibility of these boards allows them to conform to the shape of the wearer’s body, ensuring a seamless and ergonomic fit.

Rigid-flex PCBs also find extensive use in the aerospace industry. The lightweight and durable nature of these boards make them ideal for aerospace systems that require high reliability in harsh environments. From aircraft avionics to satellite communication systems, rigid-flex PCBs provide the necessary flexibility to withstand vibrations, shocks, and extreme temperatures. Furthermore, their compact design allows for efficient use of space in aircraft and satellites, where every inch matters.

Another industry that benefits greatly from rigid-flex PCBs is the medical field. The ability of these boards to withstand repeated sterilization processes and their flexibility for integration into medical devices make them a perfect fit for healthcare applications. From pacemakers to medical implants, rigid-flex PCBs offer the reliability and performance needed in critical medical devices. They also enable the creation of wearable medical devices that can continuously monitor vital signs and transmit data to healthcare professionals.

Designing rigid-flex PCBs requires careful consideration of several factors to ensure optimal performance and reliability. One important aspect is determining the appropriate bend radius for the flexible portions of the board. The bend radius should be chosen based on the materials and components used, as well as the expected flexing requirements of the application. A smaller bend radius may lead to stress on the board, while a larger bend radius may result in excessive flexing, potentially damaging the circuitry.

Another consideration is the placement of components and traces on the flexible portions of the board. Components should be positioned in a way that minimizes stress on the board during flexing. Traces should be routed in a way that avoids sharp angles and excessive bending, as these can lead to signal integrity issues and potential failure. Careful attention should also be given to the selection of materials, ensuring they can withstand the intended environmental conditions and repeated flexing.

The manufacturing process of rigid-flex PCBs involves a combination of traditional PCB manufacturing techniques and specialized processes for the flexible portions. The process begins with the fabrication of rigid PCBs, which involves the deposition of conductive layers on a rigid substrate, drilling of vias, and etching of traces. Once the rigid portions are complete, flexible materials are added to the design, which are typically polyimide or similar materials with high flexibility and temperature resistance.

The flexible materials are laminated onto the rigid portions, and the necessary conductive layers are added to create the flexible circuitry. The layers are then bonded together, and the excess material is removed through etching or mechanical milling. Finally, the components are mounted onto the rigid-flex PCB using surface mount technology or through-hole technology, depending on the design requirements.

The manufacturing process of rigid-flex PCBs requires specialized equipment and expertise to ensure the integrity of the flexible portions. The use of advanced technologies such as laser drilling and precision bonding is crucial to achieve high-quality and reliable rigid-flex PCBs.

While rigid-flex PCBs offer numerous advantages, the cost factor is an important consideration for many manufacturers. The cost of rigid-flex PCBs can be higher compared to traditional PCBs due to the additional manufacturing steps and specialized materials involved. The complexity of the design and the volume of production also impact the overall cost.

However, it’s important to consider the long-term benefits of using rigid-flex PCBs. The improved reliability and reduced assembly time can result in cost savings in the long run. Moreover, the compact design and lightweight nature of rigid-flex PCBs can lead to savings in terms of materials, transportation, and overall product size. When weighing the cost of rigid-flex PCBs against the advantages they offer, it becomes clear that the investment is often worthwhile.

While rigid-flex PCBs offer many advantages, they also come with their own set of challenges. One common challenge is ensuring proper signal integrity and impedance control in the flexible portions of the board. The flexibility of the board can introduce signal degradation and impedance mismatch, which can affect the overall performance of the circuit. To overcome this challenge, careful attention should be given to the design and routing of traces, as well as the selection of appropriate materials with low dielectric loss.

Another challenge is the reliability of the flexible portions, which are subject to repeated bending and flexing. The choice of materials and the design of the board should take into account the expected flexing requirements and environmental conditions. Reinforcing the flexible areas with additional layers or support structures can help improve the durability of the board. Additionally, conducting thorough testing and validation of the design before mass production is crucial to ensure the reliability of rigid-flex PCBs.

Rigid-flex PCB technology is continuously evolving, and several trends are shaping its future. One trend is the miniaturization of electronic devices, which is driving the demand for smaller and more flexible circuit boards. As consumer electronics become increasingly compact, rigid-flex PCBs will play a crucial role in enabling the development of slim and lightweight devices.

Another trend is the integration of advanced functionalities into rigid-flex PCBs. With the rapid advancements in sensor technology, wireless communication, and data processing, there is a growing need to integrate these functionalities into electronic devices. Rigid-flex PCBs provide the necessary flexibility and design freedom to incorporate complex functionalities into compact devices.

Furthermore, the development of new materials with enhanced flexibility and durability is opening up new possibilities for rigid-flex PCBs. Materials such as stretchable conductors and self-healing polymers are being explored to further improve the flexibility and reliability of these circuit boards. These advancements will enable the creation of even more innovative and resilient electronic devices.

Several industries have already embraced the advantages of rigid-flex PCBs and implemented them in their products. One notable example is the automotive industry, where rigid-flex PCBs are used in vehicle control systems. These boards provide the necessary durability and reliability to withstand the harsh conditions of automotive environments, while also offering space-saving benefits. Rigid-flex PCBs have contributed to the development of advanced driver assistance systems, infotainment systems, and electric vehicle technologies.

Another industry that has benefited from rigid-flex PCBs is the consumer electronics sector. From smartphones to tablets, rigid-flex PCBs have allowed manufacturers to create sleek and compact devices without compromising performance. The flexibility of these boards enables the development of foldable and curved displays, which have become increasingly popular in the consumer electronics market.

Rigid-flex PCBs offer unmatched flexibility, durability, and design freedom, making them a game-changer in the world of electronics. Their ability to reduce the need for interconnects, maximize space utilization, and withstand challenging environments make them highly suitable for a wide range of applications. While there are design considerations, manufacturing challenges, and cost factors to consider, the long-term benefits of using rigid-flex PCBs outweigh the initial investment.

As technology continues to advance and the demand for smaller, more powerful, and more flexible electronic devices increases, rigid-flex PCBs will play a crucial role in shaping the future of electronics. By unlocking new possibilities and pushing the boundaries of design, these innovative circuit boards are paving the way for the next generation of electronic devices. So, if you’re looking to create cutting-edge products with enhanced performance and reliability, it’s time to explore the advantages of rigid-flex PCBs and unlock the endless possibilities they offer.