Even if the trend of PCB manufacturing and usage is small, it will also affect consumers.

Although there may be more time, the following four main technology trends are expected to maintain the leading position in the PCB market for a long time and lead the whole PCB industry to different development directions.

1. High density interconnection and miniaturization

When computers were first invented, some people might spend their entire lives working on computers that occupy the entire wall. Today, even calculators and watches are orders of magnitude larger than the behemoths, let alone smartphones.

At present, the whole manufacturing industry is in the sight of innovation whirlwind, most of which are for miniaturization.

Across the entire consumer group, people seem to be increasingly inclined to smaller electronics.

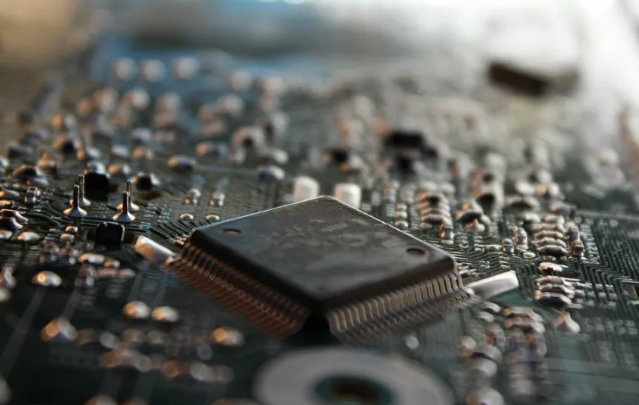

Because PCB is an important basic component in electronic products, PCB must also pursue miniaturization unremittingly.

Especially in PCB market, this means using high density interconnection technology. The further improvement of

HDI PCB technology will further reduce the size of PCB and touch more and more industries and commodities in the process.

2. Advanced materials and green manufacturing

Nowadays, PCB industry is affected by some very practical factors such as climate and social pressure. PCB manufacturing process needs to keep up with the trend of the times and evolve in the direction of sustainable development.

In fact, when it comes to the crossroads of development and environmental protection, PCB manufacturers have always been a hot topic. For example, the introduction of lead-free solder requires more energy-intensive manufacturing processes. Since then, the industry has been forced to find a new balance.

In other areas, PCB has always been in the lead. Traditionally, PCBs are made from glass fiber, which is regarded as a relatively environmentally friendly material by most people. Further progress may allow glass fibers to be replaced by materials more suitable for high data transfer rates, such as resin coated copper and liquid crystal polymers.

3. Wearable devices and pervasive computing

How to achieve greater complexity on thinner boards? Now we put this concept into practice. PCB is reducing the thickness and increasing the function every year. Now we have many practical applications of small circuit boards.

In the past decades, consumer electronics as a whole has been an important driving force for PCB manufacturing and use. Now wearable devices have entered this field, and began to become a reliable consumer product type, related PCB will also appear.

Like smart phones, wearable technologies require PCBs, but they go further. They pay more attention to design efficiency than the past technology can achieve.

4. Health and medical technology and public supervision

The introduction of modern digital technology into medicine has been one of the greatest developments in modern human history. Today’s technology means we can store patient records securely in the cloud and manage them through apps and smartphones.

However, the rapid development of medical technology has also affected PCB in some very interesting ways, and vice versa. On board camera is a new development, and can even be fixed to the PCB itself. The medical significance is huge: when the camera needs to be inserted into the human body, swallowed by the human body or introduced into the human body in other ways, the smaller the camera is, the better. Now some of the onboard cameras are small enough to be swallowed.

As for public supervision, onboard cameras and smaller PCBs can also help. For example, tachographs and vest cameras have shown a useful role in mitigating violations, and many consumer technologies have emerged to meet this demand. Many popular mobile accessory companies are exploring ways to provide drivers with ever smaller, less dramatic dashboard cameras, including and including connected hubs to interact with your phone while you’re driving.

New consumer technologies, advances in medicine, breakthroughs in manufacturing and strong trends of the times are fascinating. It’s incredible that PCB has the opportunity to be the core of all this.

This means it’s an exciting time to get into the field.

In the future, what other technologies will bring new development to PCB market? Let’s keep looking for answers.