What is High Tg PCB

High Tg PCB stands for “High Glass Transition Temperature Printed Circuit Board.” The glass transition temperature (Tg) is a critical parameter in PCB material selection, and a high Tg PCB is designed to withstand higher temperatures without undergoing a change in its mechanical or electrical properties. Here’s a closer look at what High Tg PCBs are and why they are important:

1. Glass Transition Temperature (Tg): The Tg of a material is the temperature at which it transitions from a rigid, glassy state to a more flexible, rubbery state. In the context of PCBs, it’s crucial because it determines the temperature at which the substrate material can start to soften, warp, or experience changes in its electrical properties.

2. Importance of High Tg PCBs:

- Temperature Resistance: High Tg PCBs are specifically designed to withstand elevated temperatures, making them suitable for applications where the PCB may be exposed to high temperatures during manufacturing processes or operation.

- Reliability: High Tg PCBs are more reliable in high-temperature environments because they maintain their structural integrity and electrical performance at elevated temperatures.

- Lead-Free Soldering: The transition to lead-free soldering processes, which require higher soldering temperatures, has made High Tg PCBs more important. These PCBs can withstand the higher soldering temperatures without experiencing damage.

3. Typical Tg Values:

- Standard PCBs: Standard PCB materials typically have a Tg of around 130-140°C. These materials are suitable for many applications but may not be ideal for high-temperature environments.

- High Tg PCBs: High Tg PCBs, on the other hand, have a Tg value that exceeds 170°C or even higher. These materials are designed for applications that involve high-temperature soldering processes or exposure to elevated temperatures during operation.

4. Applications:

- Consumer Electronics: High Tg PCBs are used in consumer electronics like smartphones, tablets, and laptops where miniaturization and heat resistance are crucial.

- Automotive Electronics: The automotive industry employs High Tg PCBs for engine control units (ECUs), safety systems, and infotainment systems where PCBs may be exposed to elevated under-hood temperatures.

- Aerospace and Defense: In aerospace and defense applications, High Tg PCBs are chosen for their ability to withstand extreme temperature variations and harsh environmental conditions.

- Industrial Equipment: PCBs used in industrial automation and machinery often require high-temperature resistance due to the heat generated by machinery and processes.

- LED Lighting: High-power LED lighting systems generate heat, and High Tg PCBs help dissipate this heat while maintaining electrical performance.

In summary, High Tg PCBs are specially designed to withstand higher temperatures, making them crucial for various industries and applications where temperature resistance and reliability are paramount. When selecting a PCB material, understanding the Tg value and its relevance to your specific application is essential to ensure the long-term performance and durability of your electronic devices or systems.

Choose a suitable supplier of High TG PCB

Choosing a suitable supplier for High Tg (High Glass Transition Temperature) PCBs is a critical decision to ensure the quality and reliability of your printed circuit boards. Here are steps and considerations to help you select the right supplier:

- Define Your Requirements:

- Clearly define your High Tg PCB requirements, including specifications, quantity, layer count, board thickness, and material preferences.

- Supplier Research:

- Conduct thorough research to identify potential suppliers. Sources may include industry trade shows, online directories, recommendations from colleagues, and web searches.

- Focus on suppliers with experience in manufacturing High Tg PCBs and a strong track record of delivering quality products.

- Quality and Certification:

- Verify if the supplier holds relevant quality certifications, such as ISO 9001 or ISO 14001, indicating a commitment to quality and environmental standards.

- Ask for samples or references to evaluate the quality of their previous work, especially for High Tg PCBs.

- Manufacturing Capabilities:

- Evaluate the supplier’s manufacturing capabilities, including their equipment, technology, and production capacity. Ensure they can meet your volume and technical requirements.

- Check if they have experience with the specific High Tg material you require.

- Material Selection:

- Confirm that the supplier offers High Tg materials that match your temperature resistance needs. Popular materials include FR-4 High Tg, FR-408, and others with Tg values exceeding 170°C.

- Inquire about the availability of materials with the appropriate dielectric constant (Dk) and dissipation factor (Df) for your RF or high-frequency applications.

- Cost and Pricing:

- Request detailed price quotes from multiple suppliers. Consider not only the initial PCB cost but also any additional charges for customization, tooling, shipping, and other services.

- Be cautious of significantly lower prices, as this could indicate a compromise in quality.

- Lead Times and Turnaround:

- Discuss lead times and production turnaround with potential suppliers. Ensure they can meet your project timeline.

- Consider the flexibility of lead times for future orders.

- Communication and Support:

- Evaluate the supplier’s communication and customer support. A responsive and communicative supplier can help address issues and concerns promptly.

- Ensure they have a support system in place for technical questions, troubleshooting, and post-sales support.

- Quality Control and Testing:

- Inquire about the supplier’s quality control and testing processes. They should have rigorous quality checks in place to identify and rectify defects, especially for High Tg PCBs.

- Ask about testing methods for High Tg materials and their experience with reliability testing.

- Environmental and Ethical Considerations:

- Assess the supplier’s commitment to environmental sustainability and ethical practices, which can be important for compliance with regulations and your company’s values.

- Logistics and Shipping:

- Consider the supplier’s location and shipping options. A PCB supplier with a convenient location and flexible shipping arrangements can save time and costs.

- Contract and Payment Terms:

- Review the supplier’s contract terms, payment conditions, and warranty policies to ensure they are fair and reasonable.

- References and Reviews:

- Seek references from other customers who have worked with the supplier. Online reviews and testimonials can also provide insights into their reputation and reliability.

- Visit the Supplier:

- If feasible, consider visiting the supplier’s facilities to get a firsthand look at their operations and capabilities.

Choosing the right supplier for High Tg PCBs is essential to ensure the durability and performance of your electronic products in high-temperature environments. Invest time in the selection process to establish a successful and long-term partnership.

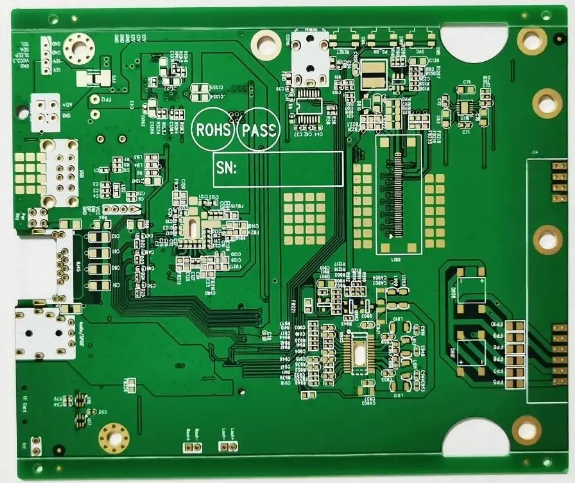

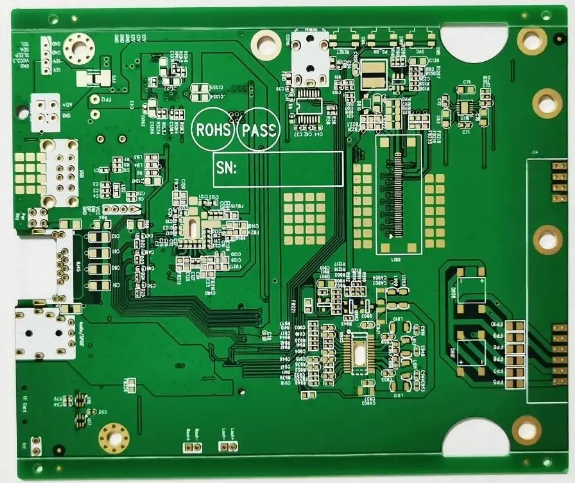

PCBSky has high TG PCBs for sale, contact us now.

Main Equipments