How often do you start the PCB development process and are bothered by time-consuming management tasks? Once ready for production, a design review and correction of DFM issues will be required, which will take your own time. With the acceleration of product development progress and the shortening of product life cycle, the pressure of increasing the iteration speed of pcb prototype is increasing without sacrificing cost or quality.

So, how can PCB design team keep its development progress normal without sacrificing quality or risking prototype development failure? For any project, there are a series of important management and auxiliary design tasks, but they only take up too much time in the development process. In addition, some tasks in the design process make collaboration cumbersome and slow down the overall process of the design team. When designers can collaborate more effectively, they can narrow the gap in the operation of

pcb prototype design and complete the products of each iteration quickly without reducing the quality.

The process of improving the iteration speed of pcb prototype

Engineering teams working on complex projects may find it difficult to keep everything in order. Design teams need to develop accurate specifications, functional requirements, user experience requirements, and product delivery schedules, and they need to assign tasks to combine manufacturable PCB layouts. Good CAD tools are important, they will help everyone maintain productivity, but when it comes to putting boards into production, CAD tools will become secondary tools.

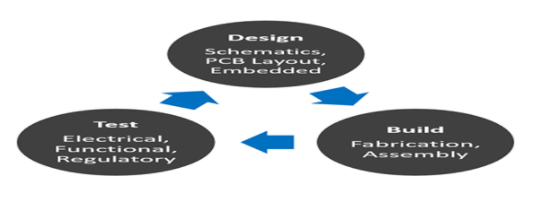

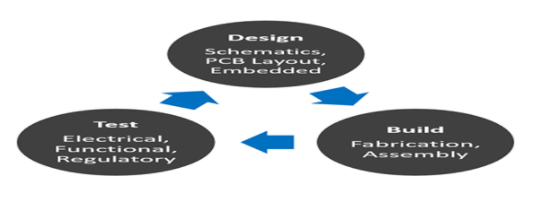

Once you enter the PCB prototyping stage, things will become cyclical as prototypes are produced, tested, redesigned and repeated. Send the design to the manufacturer for review, pass the required changes back to the designer, and the customer may need to review the proposed changes and then repeat the process before prototyping. Finally, your prototype is produced and sent back to the field for testing. If a new revision is required, you have just finished the prototyping process cycle and you will need to order another printed circuit board.

Design build and test iterations as part of the hardware development process

Whether you use agile methods or other development processes, improving the speed of PCB prototyping should not sacrifice quality. It should also allow everyone involved in the process to reach out to the design at the right time, while tracking revision history and maintaining the appropriate level of user access.

Designers use their local design tools and cloud based data sharing / project management tools for normal collaborative processes.

After the design is released, the manufacturer will go through the normal design review process and place notes in the design documents to mark the changes.

Designers should make changes and prepare the final version for production. The manufacturer can then receive this information and put the board into manufacture and assembly.

Ideally, test requirements should be developed prior to manufacturing, although they may need to be updated during

PCB manufacturing / assembly. If any on-line tests are planned during the manufacturing process, these data need to be provided to the manufacturer.

After internal testing, the design team can define new requirements and plan any redesign, or they can start new revisions.

Each step takes its own time, and putting the design into production can be time-consuming when you need to go back and forth with the manufacturer and assembler. When your team works remotely, everyone tends to rely on email links, video chats, and even phone calls to make the necessary design changes to get the new prototypes into production. Now, with cloud based collaboration tools for hardware development, designers can change this dynamic and quickly complete each prototype iteration.

Change pcb prototype dynamics

What if you can eliminate unnecessary back and forth communication between most PCB design teams and simplify the process of prototype iteration? If you can bring manufacturers into the same environment as the design team, you can speed up design reviews and get to production faster during each revision.

When these sharing and collaboration tools are integrated into your PCB design software, this will be done as quickly as possible without loss of quality. Being able to share design data among all stakeholders helps speed up some of the key tasks that need to be done before starting a pcb prototype iteration:

DFM marking design changes. Design changes can be placed as comments on board areas, specific locations in the design, or components in design documents. In this way, your team members or manufacturers can easily bring up any changes required to meet DFM.

Parts procurement. The supply chain moves rapidly, and those components selected at the start of design may not be available for manufacturing. Cloud based collaborative tools in PCB design software ensure that your manufacturer can help you select alternatives and quickly introduce them into the BOM before production.

Revision tracking. No matter who modifies the project, if you need to restore the design, you can access the old revisions as needed. Cloud platforms using git provide a simple way to track revisions as you go through design reviews and future prototype iterations.

Output file generation. Sometimes, your manufacturer needs to take the lead in generating output files from your design. Granting them access through the cloud can speed up the process and eliminate email back and forth between stakeholders.