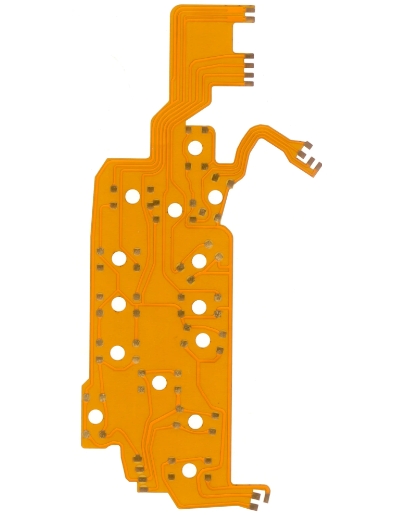

As a special interconnection technology, the multilayer flexible printed board can reduce the assembly size and weight of electronic products, avoid wiring errors, and realize three-dimensional assembly under different assembly conditions. It has the characteristics of light, thin, short and small, and has been widely used in computers, avionics and military electronic equipment. However, multilayer flexible printed boards also have the disadvantages of complicated process, high manufacturing cost, and difficult to modify and repair.

The multilayer flexible printed board is to bond two rigid outer layers on the flexible printed circuit board. The circuit on the rigid layer and the circuit on the flexible layer communicate with each other through metallized holes. Each rigid flexible printed board has one or more rigid regions and one or more flexible regions.

Commonly used flexible dielectric films include polyesters, polyimides, and Poly fluorides. The selection of flexible dielectric film should be comprehensively investigated from the heat resistance performance, coating performance and thickness of the material. Commonly used adhesive films are mainly acrylic, epoxy and polyester. The choice of adhesive film is mainly to investigate the fluidity and thermal expansion coefficient of the material.