In the world of military technology, precision is not just a desired attribute; it is an absolute necessity. The seamless coordination of complex systems, the reliability of communications, and the accuracy of targeting all depend on the meticulous construction of every electronic circuit. At the heart of this precision lies the unwavering commitment of military electronics PCB manufacturers.

In an era where national security and defense capabilities rely heavily on cutting-edge electronics, the role of printed circuit boards (PCBs) cannot be overstated. These unassuming, yet vital, components form the backbone of modern military systems, from radar installations to communication networks and sophisticated weaponry.

The manufacturer’s commitment to precision starts at the very core of their operations. Each circuit, no matter how small or intricate, is crafted with exacting standards and rigorous attention to detail. The materials used are chosen not just for their quality, but for their ability to withstand the harshest of conditions, be it the scorching heat of a desert battlefield or the icy cold of high-altitude missions.

But it’s not just about meeting specifications; it’s about surpassing them. Military electronics PCB manufacturers understand that in the defense industry, there’s no room for error. A single glitch, a minor malfunction, could have catastrophic consequences. Therefore, their commitment goes beyond the production floor; it extends to comprehensive quality control processes, testing methodologies that leave no room for doubt, and continuous innovation to stay ahead of emerging threats.

In this exploration of the military electronics PCB manufacturing world, we delve into the intricacies of this commitment to precision. We’ll uncover the advanced technologies, the stringent protocols, and the passionate dedication that go into every circuit, ensuring that when our nation’s security is on the line, precision is the only option. Join us on this journey through the heart of defense technology, where every circuit carries the weight of a nation’s safety and security.

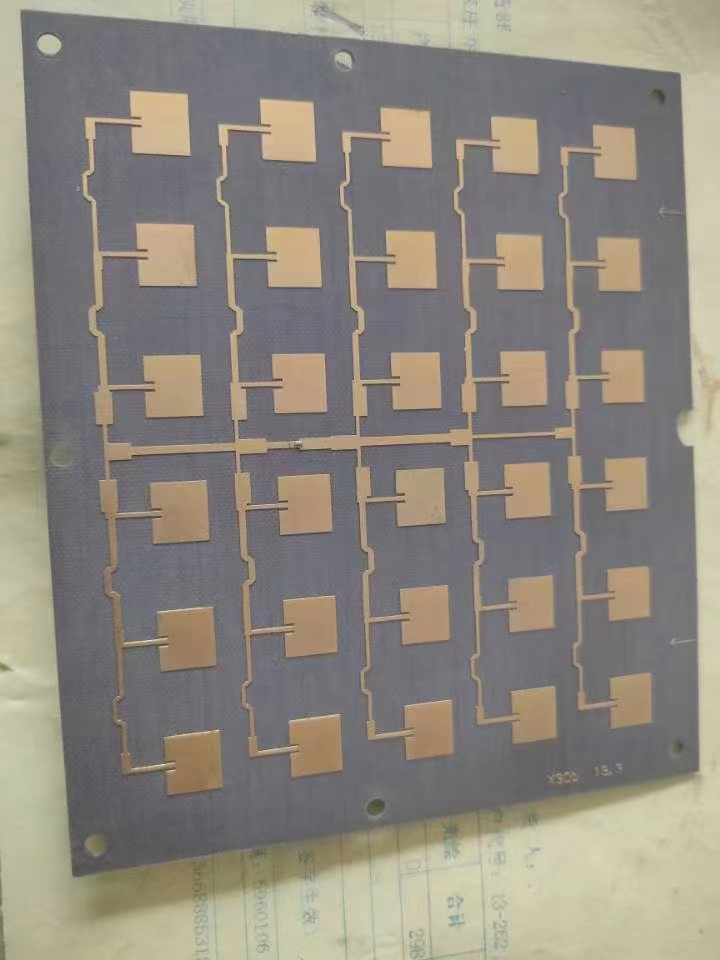

Designing for Perfection: The Art of Precision Engineering In the realm of military electronics PCB manufacturing, design serves as the cornerstone of every project. Manufacturers prioritize precision engineering to transform designs into reliable circuit boards. This demands a high level of specialized engineering knowledge to ensure precise placement, layout, and connections of each component. Designers consider the shortest signal paths to minimize signal interference. This design philosophy underpins the reliability and performance of the circuit boards.

Prototyping Excellence: Turning Concepts into High-Performance PCBs Manufacturers not only plan meticulously during the design phase but also utilize prototyping to test and validate design effectiveness. Prototyping not only helps uncover potential issues but also accelerates the product development cycle. By rapidly creating and testing multiple prototypes, manufacturers can adjust designs to ensure superior PCB performance.

Materials Matter: Selecting the Right Components for Durability and Reliability The reliability of military electronics PCBs heavily depends on the materials used. Manufacturers carefully select materials, considering their conductivity, heat resistance, durability, and performance in harsh conditions. These materials not only meet the highest military standards but also ensure the PCBs’ reliability under extreme conditions, meeting the demands of military applications.

Beyond Standards: The Rigorous Testing Regimens Military electronics PCB manufacturers uphold quality control that goes beyond industry standards. They implement strict testing protocols to ensure every PCB undergoes comprehensive testing before being delivered to customers. This includes signal integrity testing, temperature and humidity testing, vibration and shock testing, and more to validate performance under various conditions.

A Zero-Defect Philosophy: The Quest for Perfection In the realm of military electronics, a zero-defect philosophy is the goal. Manufacturers adopt a zero-tolerance approach to defects, striving for excellence to ensure that each PCB is free from any flaws. They achieve this goal through visual inspections, automated testing, and manual inspections, among other multi-layered quality control measures.

Securing Reliability: Environmental Testing and Endurance Trials To ensure PCBs operate reliably under various environmental conditions, manufacturers conduct environmental testing and endurance trials. These tests include subjecting PCBs to extreme temperatures, humidity, and vibrations to simulate real-world usage. Only through such testing can PCBs earn reliability certifications.

Adapting to Emerging Threats: Staying One Step Ahead Military electronics PCB manufacturers understand that threats continually evolve. Therefore, they not only cater to existing needs but also innovate to address emerging threats. They actively monitor the latest technological trends and incorporate them into product design and manufacturing to ensure military systems always possess the latest defense and communication capabilities.

Advanced Materials and Manufacturing: Pioneering Breakthroughs By adopting advanced materials and manufacturing techniques, manufacturers drive advancements in military electronics PCBs. They constantly seek new materials to enhance PCB performance and durability. This innovative spirit allows them to pioneer breakthroughs and offer unprecedented solutions for defense.

Revolutionizing Military Electronics: A Glimpse into the Future Manufacturers’ innovative efforts not only improve existing systems but also have the potential to transform future defense technology. They explore emerging technologies like quantum computing and advanced communication protocols to open up entirely new possibilities for military applications. The future of this field holds limitless potential.

Extreme Conditions, Unyielding Performance: Surviving and Thriving Military electronics PCBs must operate in various extreme conditions, from scorching desert heat to freezing high-altitude environments. Manufacturers understand this and design and test their circuit boards to ensure exceptional performance in these harsh conditions. The durability and reliability of these circuit boards are paramount on the battlefield, where they must perform flawlessly.

From Scorching Deserts to Frozen Tundras: Real-World Testing To validate how circuit boards perform in real-world battlefield conditions, manufacturers conduct field testing. This may involve deploying circuit boards in diverse climate conditions and subjecting them to prolonged usage. Such real-world testing is critical to ensuring circuit boards deliver as expected during critical missions.

Keeping Communications Clear: The Crucial Role in Tactical Operations In modern military operations, communication is of paramount importance. Military electronics PCB manufacturers understand this and focus on ensuring the reliability of communication equipment. Whether in a command center or on a soldier’s tactical gear, circuit boards must maintain clear communication to ensure the successful completion of missions.

Forging Strong Alliances: Working Hand in Hand with the Military Manufacturers establish close partnerships with the military to ensure circuit boards meet the defense department’s needs. They understand military requirements and specifications, customizing solutions to meet specific military application demands. This collaboration ensures the seamless integration of military electronics PCBs into defense systems.

Custom Solutions for Unique Challenges: Tailoring PCBs to Mission Needs Different military missions and applications come with varying requirements, necessitating the ability to customize circuit boards to meet these needs. Manufacturers exhibit flexibility, adjusting designs and manufacturing processes to align with the specific requirements of each mission. This personalized approach ensures military electronics PCBs are capable of handling diverse tasks.

Global Reach, Local Support: The Network of Military Electronics Manufacturers Military electronics PCB manufacturers build a global network to provide local support. Regardless of where military operations take place, manufacturers can offer quick maintenance and support, ensuring equipment availability and performance.

The Guardians of National Security: PCB Manufacturers’ Crucial Role Manufacturers recognize their significance in national security. They bear the responsibility of safeguarding national security by providing reliable electronic equipment to support defense missions. Their work directly impacts a nation’s security and defense capabilities.

Cybersecurity in the Age of Electronics: Safeguarding Data and Operations With the proliferation of electronic devices, cyber threats are on the rise. Manufacturers are cognizant of the importance of cybersecurity and take measures to ensure the reliability of circuit boards in defending against cyberattacks. They collaborate with the military to collectively protect critical data and operations.

A Bright Future Ahead: The Enduring Commitment to Precision and Excellence The future holds great promise for military electronics PCB manufacturers. They will continue their efforts, continually improving circuit board performance to address evolving threats and demands. They remain steadfast in their commitment to precision and excellence, ensuring that defense systems consistently operate at peak levels.

Military electronic PCBs (Printed Circuit Boards) find extensive applications in the military domain, enhancing and supporting various critical military equipment and systems. Here are some primary application areas of military electronic PCBs:

1. Communication Systems: Military electronic PCBs are used in various communication devices, including radios, satellite communication, radar, communication terminals, and network equipment. These circuit boards ensure reliable communication within the military and with command centers to facilitate coordination and command of military operations.

2. Navigation and Positioning Systems: In missiles, aircraft, ships, and vehicles, military electronic PCBs support GPS, inertial navigation systems, and other location positioning technologies. These systems enable precise navigation and target positioning in complex environments.

3. Weapons and Fire Control Systems: Weapon systems such as missiles, tanks, aircraft, and warships rely on precision electronic PCBs to ensure accurate targeting and firing. These circuit boards contribute to improved accuracy and effectiveness of weapon systems.

4. Intelligence and Surveillance Equipment: Military intelligence and surveillance equipment, such as reconnaissance satellites, drones, reconnaissance aircraft, and intelligence gathering devices, use electronic PCBs to process and transmit intelligence data. These circuit boards play a critical role in intelligence acquisition and sharing.

5. Electronic Warfare and Jamming Systems: Electronic warfare equipment is used to jam, disrupt, or protect communication and radar systems. Military electronic PCBs support the operation of electronic warfare equipment, ensuring its effective mission execution.

6. Monitoring and Control Systems: Monitoring systems and control centers use electronic PCBs to track military activities, monitor sensor data, analyze intelligence, and support decision-making.

7. Armored Vehicles and Aircraft: Electronic PCBs are used in various systems of armored vehicles (such as tanks and infantry fighting vehicles) and aircraft (such as fighter jets and helicopters), including communication, navigation, weapon control, and flight control.

8. Survival Gear: Soldiers’ survival gear, including helmets, armor, and reconnaissance equipment, also incorporates electronic PCBs to support survival, communication, and intelligence collection needs.

These are just some examples of the applications of military electronic PCBs in the military domain. As technology continues to advance, the role of these circuit boards in supporting modern military operations becomes increasingly crucial, contributing to enhancing the military’s combat capabilities and effectiveness.