In today's fast-paced technological landscape, the demand for cutting-edge electronics has never been greater. From wearable devices to aerospace applications, flexible PCBs have become the backbone of innovation. At the heart of this electronic revolution lies the expertise of reliable manufacturers who understand the intricacies of flexible PCB production.

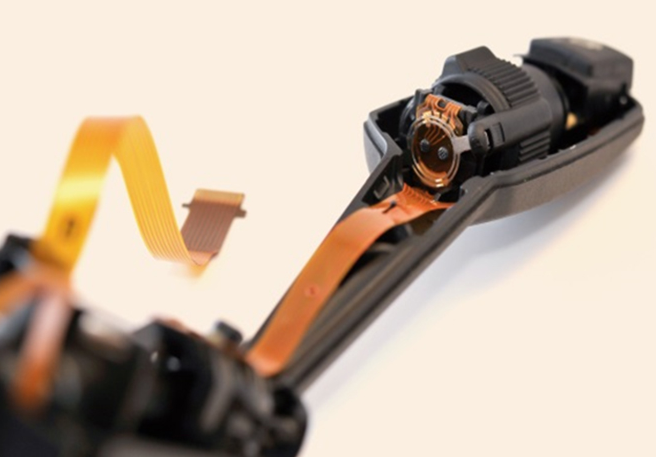

Flexible circuit boards, or Flex PCBs, represent a remarkable leap in electronic engineering. These bendable, lightweight boards are designed to adapt to the contours of your product, enabling a seamless integration of electronic components. But the true magic happens in the manufacturing process. Our cutting-edge expertise allows us to craft Flex PCBs with precision, using advanced materials and techniques that were once considered the stuff of science fiction.

When it comes to flexible PCBs, cutting-edge expertise is non-negotiable. Our dedicated team of engineers and technicians stays ahead of the curve, constantly pushing the boundaries of what Flex PCBs can achieve. We understand that every project is unique, and that's why our expertise shines. From designing intricate circuits to ensuring optimal flexibility and durability, we bring a holistic approach to Flex PCB manufacturing. By choosing a partner with cutting-edge expertise, you're not just getting a product; you're investing in the future of your innovation.

In the ever-evolving landscape of electronic technology, having a trusted partner in flexible PCB manufacturing is essential. Flexible printed circuit boards, or Flex PCBs, have become a cornerstone of innovation, and finding a reliable manufacturer can make all the difference in the success of your projects.

At the heart of every successful electronic device lies the reliability of its internal components. Flexible PCBs play a pivotal role in ensuring these components function flawlessly, especially in applications where flexibility, durability, and compactness are key requirements. As a trusted partner in flexible PCB manufacturing, our commitment to delivering dependable solutions is unwavering.

Every project is unique, and cookie-cutter solutions won't suffice. That's where our expertise shines. We understand the importance of tailored solutions that align with your specific requirements. Whether you're developing a medical device, an automotive application, or a cutting-edge consumer gadget, we have the knowledge and experience to craft flexible PCBs that meet your exact specifications. Our commitment to customization ensures that your project's potential is fully realized.

In the world of flexible PCB manufacturing, quality assurance is paramount. From the selection of high-quality materials to the precision of our manufacturing processes, we leave no room for compromise. Our dedication to quality extends to rigorous testing and inspection, ensuring that every Flex PCB we produce meets the highest industry standards. With us as your trusted partner, you can have confidence in the reliability and performance of your electronic creations.

In the realm of flexible electronics, the pursuit of high-quality solutions is paramount. These innovative electronic devices, often characterized by their flexibility and adaptability, have revolutionized industries ranging from healthcare to aerospace. To achieve excellence in flexible electronics, partnering with a manufacturer that prioritizes quality is essential.

Flexible electronics have opened up new frontiers in design and functionality. From flexible displays to wearable health monitors, these devices require flexible circuitry that can withstand continuous bending and stretching while maintaining electrical integrity. High-quality solutions in flexible electronics involve the use of top-grade materials and advanced manufacturing techniques, all of which contribute to the longevity and reliability of these products.

At the heart of our commitment to high-quality solutions lies a dedication to research and development. We understand that staying at the forefront of flexible electronics requires continuous innovation. That's why our team of experts continually explores new materials and technologies to enhance the performance and durability of our products.

In the world of flexible electronics, reliability is paramount. Whether it's a flexible sensor for a medical device or a rollable display for a consumer gadget, the end-users depend on seamless functionality. High-quality solutions ensure that these devices perform as intended, providing a positive user experience and bolstering your brand's reputation.

In conclusion, the world of flexible electronics is a realm of limitless possibilities. As these devices continue to reshape industries and improve our daily lives, the importance of high-quality solutions cannot be overstated. By partnering with a manufacturer that shares your commitment to excellence, you can be at the forefront of the flexible electronics revolution, delivering products that inspire and endure.

In the dynamic world of electronic innovation, one size does not fit all. Customization is the key to creating electronic solutions that perfectly match your unique needs and objectives. When it comes to flexible circuit board manufacturing, the ability to provide customized designs is a hallmark of a trusted partner.

Customization begins with understanding your project's specific requirements. Whether you're designing a compact wearable device or a complex aerospace application, our team of experts will collaborate closely with you to grasp the nuances of your project. We take into account factors like form factor, environmental conditions, and performance expectations to tailor a design that fits like a glove.

Our commitment to customization extends beyond the design phase. We leverage cutting-edge technologies and materials to ensure that your flexible PCBs are optimized for your application. From materials selection to manufacturing processes, every aspect is fine-tuned to meet your needs.

The advantages of customized designs are far-reaching. They not only enhance the functionality and performance of your devices but also provide a competitive edge. In a crowded marketplace, having a unique and tailored solution can set your product apart and attract a broader audience.

In conclusion, when it comes to flexible PCB manufacturing, one size does not fit all. Customized designs are the foundation of success in electronic innovation. By partnering with a manufacturer that prioritizes customization, you can ensure that your electronic devices are finely tuned to meet your project's unique demands.

In the realm of flexible PCB manufacturing, unparalleled performance and reliability are the gold standards that every customer seeks. Flex PCBs are designed to deliver top-notch performance while withstanding the rigors of diverse applications. Choosing a manufacturer that excels in producing Flex PCBs with unmatched quality is crucial for your project's success.

Performance and reliability go hand in hand when it comes to flexible PCBs. These boards are commonly employed in applications where flexibility, durability, and adaptability are paramount. Whether it's a medical device, aerospace system, or wearable technology, the performance of Flex PCBs directly influences the overall functionality and longevity of the final product.

Our commitment to unparalleled performance begins with a rigorous selection of materials and a deep understanding of your project's requirements. We take into account factors such as thermal management, signal integrity, and electrical performance to design Flex PCBs that excel in your specific application.

Reliability is the linchpin of our manufacturing process. We employ strict quality control measures and testing protocols to ensure that every Flex PCB we produce meets the highest industry standards. This dedication to reliability ensures that your electronic devices can withstand the demands of the real world, delivering consistent performance over time.

In today's competitive landscape, the reputation of your brand hinges on the performance and reliability of your products. Partnering with a manufacturer that shares your commitment to excellence is an investment in the long-term success of your projects. With unparalleled performance and reliability as our guiding principles, we are your trusted ally in the world of Flex PCB manufacturing.

In the world of flexible circuit board manufacturing, experience and know-how are invaluable assets. Industry-leading experience is a testament to a manufacturer's ability to adapt,innovate, and consistently deliver high-quality solutions. When it comes to flexible circuit board expertise, our track record speaks volumes.

Our journey in the industry has been marked by a commitment to continuous learning and adaptation. With each project, we have gained valuable insights into the evolving demands of various sectors, from healthcare to telecommunications. This wealth of experience positions us as a reliable partner capable of navigating the complexities of diverse applications.

Industry-leading experience is not merely about the number of years in operation; it's also about the depth of knowledge acquired along the way. Our team of experts brings a wealth of technical expertise and industry-specific insights to the table. We understand the unique challenges and opportunities presented by flexible circuit board manufacturing, allowing us to provide tailored solutions that align with your project's goals.

Moreover, our experience extends beyond the technical aspects of manufacturing. We have built lasting partnerships with clients across the globe, earning a reputation for our reliability, transparency, and commitment to excellence. We understand that successful collaborations are built on trust, and our extensive experience in the industry underscores our trustworthiness as a partner.

In today's fast-paced world, having a partner with industry-leading experience and know-how is a strategic advantage. It means having a trusted advisor who can not only meet your current needs but also anticipate and address future challenges. By choosing a manufacturer with a proven track record, you gain a valuable ally in the pursuit of innovation and success.

In the realm of flex PCB manufacturing, one size does not fit all. Projects vary widely in scale, complexity, and requirements. Whether you're developing a prototype or launching a large-scale production, having a manufacturer that offers tailored solutions is essential for your project's success.

We understand the diverse needs of our clients, from startups embarking on their first product development journey to established companies scaling up their operations. Our commitment to providing tailored solutions begins with a comprehensive assessment of your project's scope, objectives, and constraints.

For smaller-scale projects and prototypes, we offer flexible manufacturing options that accommodate your budget and timeline. Our expertise in rapid prototyping ensures that you can quickly bring your ideas to life and test them in real-world conditions. This agility is crucial for startups and innovators looking to iterate and refine their designs.

For larger-scale productions, we have the capacity and infrastructure to meet your volume requirements without compromising on quality. Our manufacturing processes are optimized for efficiency and consistency, ensuring that every Flex PCB we produce meets the highest industry standards.Tailored solutions also extend to the design phase. We work closely with you to understand your project's unique challenges and opportunities, providing customized design services that align with your objectives.

In conclusion, the scale of your project should not limit your ability to access high-quality flex PCB manufacturing. By partnering with a manufacturer that offers tailored solutions, you can confidently pursue projects of all sizes, knowing that your specific needs will be met with precision and excellence.

Multi-layer Flexible PCB

Multi-layer Flexible PCB

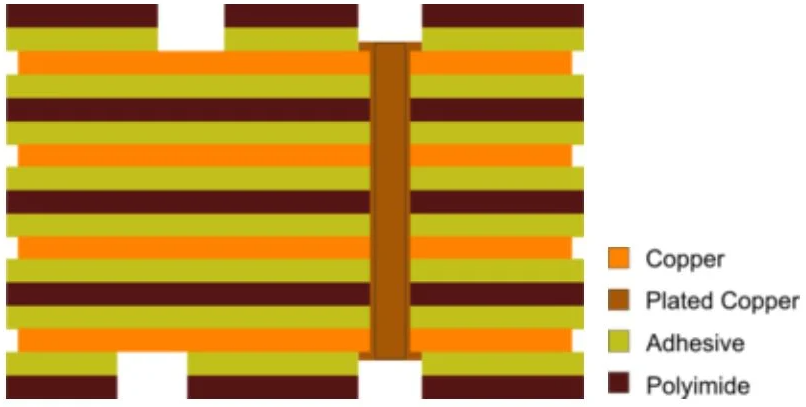

What is a Multi-layer flexible PCB? A multi-layer flexible printed circuit board (PCB) is a type of electronic interconnect technology that combines the benefits of both flexibility and multiple layers of circuitry. It is commonly used in applications where space constraints, weight reduction, and flexibility are essential. Multi-layer flexible PCBs are widely used in industries…

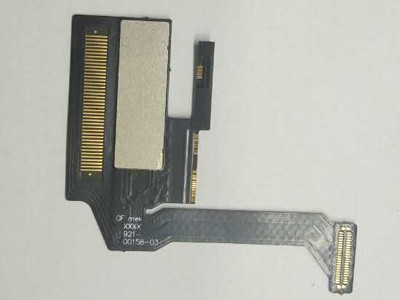

Double Sided Flexible PCB

Double Sided Flexible PCB

What is a Double-Sided Flexible PCB? A Double-Sided Flexible Printed Circuit Board (PCB) is a type of PCB that is designed to be flexible and can have circuitry on both sides of the board. Unlike traditional rigid PCBs, flexible PCBs are made of flexible materials like polyimide or polyester, allowing them to bend and conform…

Single Sided Flexible PCB

Single Sided Flexible PCB

Single-sided flexible PCBs (Printed Circuit Boards) are a type of flexible electronic circuit board that has conductive traces and components on only one side. Unlike traditional rigid PCBs, flexible PCBs are made from flexible materials like polyimide or polyester, which allows them to bend and conform to different shapes and applications. Here are some key…

In the competitive landscape of electronics, success in the market is the ultimate goal. Your products must not only meet the demands of today but also anticipate the needs of tomorrow. Partnering with a manufacturer that understands the dynamics of market success is the key to achieving your business objectives.

Our journey with clients extends beyond the manufacturing phase. We see ourselves as strategic partners invested in your long-term success. We understand the importance of time-to-market, cost-efficiency, and product differentiation in gaining a competitive edge.

Time-to-market is a critical factor in the rapidly evolving electronics industry. Our expertise in efficient manufacturing processes and rapid prototyping helps expedite your product development cycle, ensuring that you can bring your innovations to market quickly.

Cost-efficiency is another essential aspect of market success. We offer competitive pricing without compromising on quality, helping you maximize your return on investment.

Product differentiation is where our customization capabilities shine. We work closely with you to design and manufacture Flex PCBs that set your products apart. Whether it's enhancing functionality, reducing form factor, or ensuring durability, we contribute to your product's unique selling points.

Market success is not a destination but a journey. With us as your partner, you have a reliable ally on this path. Our commitment to excellence, reliability, and innovation ensures that your products are well-positioned to meet market demands and capture the attention of your target audience.

In conclusion, market success in the world of electronics requires more than just a great idea. It requires a strategic partnership with a manufacturer that shares your vision and is committed to your success. PCBSky is ready to be that partner, supporting you every step of the way on your journey to market excellence.

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 -10layers |

| Order Quantity | 1pcs - 10000+pcs |

| Build Time | 2days - 5weeks |

| Material | DuPont PI, Domestic Shengyi PI |

| Board Size | Min 6*6mm, Max240*610mm |

| Board Thickness | 0.1mm -1.0mm |

| Copper Weight (Finished) | 0.5oz - 2.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating---Soldermask oil | Green, White, Blue, Black, Red, Yellow |

| Solder-stop coating---Coverlay | PI and PET film |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL - Hot air solder leveling Lead - free HASL - RoHS ENIG - RoHS Immersion Tin - RoHS OSP - RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 8mil |

| Min. hole size---Drilling (PTH) | 0.2mil |

| Min. hole size---Punching (NPTH) | 0.5mil |

| Tolerance of dimension | ±0.05mm |

| Other Techniques | Peelable solder mask Gold fingers Stiffener (only for PI/FR4 substrate) |