In today’s fast-paced and competitive market, finding the best PCB assembly service is essential for businesses looking to maximize efficiency and quality. The right service provider can make all the difference in ensuring smooth production processes and delivering a high-quality end product. But with so many options available, how do you choose?

Enter PCBSky, the industry leader in PCB assembly services. With our expertise and commitment to excellence, we have helped countless businesses streamline their production processes, reduce costs, and deliver exceptional products to their customers. Our state-of-the-art facilities and highly skilled technicians ensure that every assembly is handled with precision, accuracy, and attention to detail.

When searching for a PCB assembly service, it’s important to consider factors such as experience, reliability, and reputation. PCBSky checks all the boxes, thanks to our years of experience in the industry and our track record of delivering outstanding results. From small-scale projects to complex, high-volume productions, we have the capabilities to meet your specific needs.

Don’t compromise on quality or efficiency. Choose PCBSky as your trusted PCB assembly service provider and experience the difference firsthand. Contact us today to discuss your requirements and let us help you take your production processes to new heights.

Selecting the right PCB assembly service is crucial for businesses aiming to optimize their production processes and deliver high-quality products. The quality of the assembly directly impacts the functionality and reliability of the end product, making it a critical aspect of any manufacturing operation. By partnering with a reputable and experienced PCB assembly service provider, businesses can ensure that their products meet the highest standards and exceed customer expectations.

When choosing a PCB assembly service, there are several key factors to consider. First and foremost is the service provider’s experience and expertise in the industry. It’s important to select a company that has a proven track record of successfully completing similar projects and has a deep understanding of the specific requirements and challenges associated with PCB assembly.

Reliability is another crucial factor to consider. A reliable PCB assembly service provider should have efficient processes in place to ensure on-time delivery and minimal disruptions to production schedules. This includes clear communication channels, effective project management, and a proactive approach to addressing any issues that may arise during the assembly process.

Reputation also plays a significant role in the selection process. It’s essential to choose a PCB assembly service provider with a strong reputation for delivering high-quality products and excellent customer service. Reading customer reviews and testimonials can provide valuable insights into the service provider’s strengths and weaknesses, helping businesses make an informed decision.

PCB assembly services can vary in terms of the types of assemblies they specialize in. It’s important for businesses to understand the different types of PCB assembly services available to ensure they select a provider that aligns with their specific needs. The three main types of PCB assembly services are:

Understanding these different types of PCB assembly services can help businesses choose the most appropriate service provider based on their specific requirements.

Ensuring the highest quality of PCB assembly is crucial for businesses looking to deliver reliable and durable products. When evaluating the quality of a PCB assembly service, several factors should be taken into consideration.

Firstly, it’s important to assess the service provider’s quality control processes. A reputable PCB assembly service provider should have stringent quality control measures in place, including thorough inspections and testing at various stages of the assembly process. This helps identify and rectify any potential defects or issues before the final product is delivered.

Additionally, the service provider should adhere to industry standards and certifications, such as ISO 9001, which demonstrate their commitment to quality and continuous improvement. Compliance with these standards ensures that the PCB assembly meets the required specifications and reliability standards.

Furthermore, the experience and expertise of the service provider’s technicians are critical factors in ensuring the quality of the assembly. Skilled technicians who are well-versed in the latest assembly techniques and equipment can significantly contribute to the overall quality of the end product.

Pricing and turnaround time are important considerations when selecting a PCB assembly service. It’s essential to strike a balance between cost-effectiveness and timely delivery without compromising on quality.

When comparing pricing among different service providers, it’s important to consider the entire cost structure, including assembly fees, component procurement, and any additional services required. Some PCB assembly service providers may offer competitive pricing for assembly but charge higher fees for component sourcing, which can significantly impact the overall cost.

Turnaround time is another critical factor, especially when dealing with time-sensitive projects. The service provider should be able to provide accurate lead times and deliver the assembled PCBs within the agreed-upon timeframe. Any delays in the assembly process can have a ripple effect on the overall production schedule, resulting in potential revenue loss and customer dissatisfaction.

The experience and expertise of a PCB assembly service provider are crucial indicators of their ability to deliver high-quality assemblies. It’s important to assess the service provider’s track record, industry experience, and the qualifications of their technicians.

A service provider with years of experience in the industry is likely to have encountered a wide range of assembly challenges and developed effective solutions. They would have refined their processes and acquired the necessary expertise to handle complex projects and meet demanding specifications.

The qualifications and training of the service provider’s technicians are equally important. Skilled and knowledgeable technicians can ensure that the assembly is executed with precision and accuracy, minimizing the risk of errors or defects. Certifications or training programs specific to PCB assembly can further validate their expertise in the field.

Customer feedback and testimonials can provide valuable insights into the quality of service provided by a PCB assembly service provider. Reading reviews and testimonials from past customers can help businesses gauge the service provider’s strengths, weaknesses, and overall customer satisfaction.

Positive feedback and testimonials are indicative of a service provider’s ability to deliver on their promises and exceed customer expectations. It’s also worth considering any negative feedback or complaints and how the service provider has addressed these issues. Responsiveness and a proactive approach to resolving customer concerns are important qualities to look for in a service provider.

Additionally, businesses can reach out to other companies in their industry or professional networks for recommendations and referrals. Personal recommendations from trusted sources can provide further assurance when selecting a PCB assembly service provider.

In addition to PCB assembly, many service providers offer a range of additional services that can further enhance the efficiency and quality of the production process. These additional services may include:

By availing these additional services, businesses can streamline their production processes, reduce the risk of errors, and improve overall efficiency.

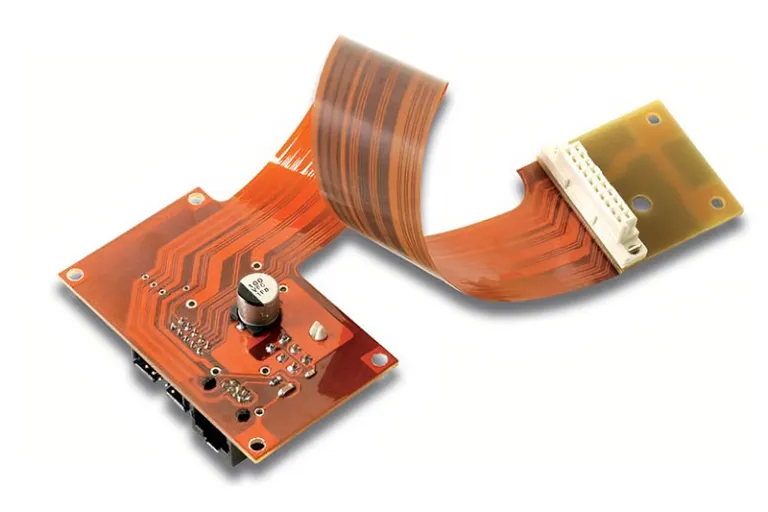

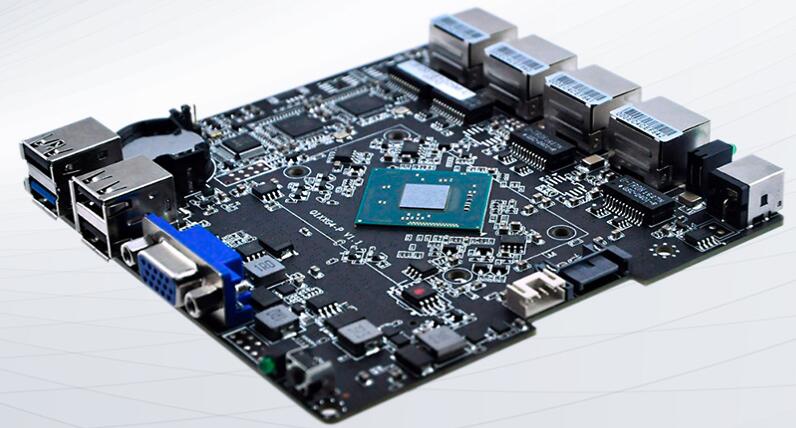

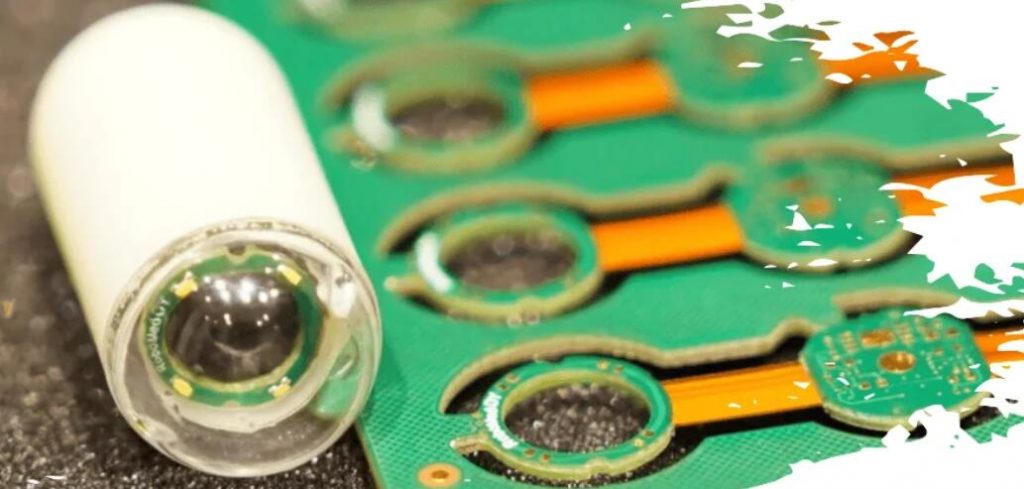

PCBSky is a national enterprise focusing on PCB manufacturing and PCBA factory for 10 years. The company has a strong engineering team and a professional electronic component procurement team to serve many domestic and foreign automotive electronics, medical electronics, power communication, industrial automation and smart home. Our customers are from various industries, and PCBSky is a one-stop manufacturing service provider integrating PCB manufacturing, electronic component acquisition, chip processing and test assembly.

Our company provides PCBA electronic manufacturing solutions for customers in developed countries and regions such as the United States, Canada, Germany, France, Hong Kong, etc., and has won good reputation, including PCB board manufacturing and SMT chip processing and other core businesses.

Self-developed SMT patch online quotation ordering system, the quotation is accurate and hidden, the procurement is efficient and convenient; the production of ERP system in the docking factory, the order situation is unobstructed, the production plan is controlled at any time, so that your PCBA and circuit board projects are in good condition.

| Material Type | ltem | MIN | MAX |

| PCB | Size(length*width*thickness) | 50*40*0.38 mm | 510*460*4.2 mm |

| Weight | 1.8 kg | ||

| Special size | 610*510*4.2 mm | ||

| Material | FR-4,CEM-1,CEM-3, Aluminum board, FPC | ||

| Surface treatment | HAL, OSP, Immersion gold, plated gold, golden finger | ||

| Electronic Components | Chip and IC | 0402 (1.0*0.5) | 22*22 |

| Special size(connector) | 1.6*0.8 | 72 mm | |

| BGA pitch | 0.3 mm | 1.0 mm | |

| QFP pitch | 0.3 mm | 1.0 mm | |

| Prodcut Type | Product Quantity | Normal delivery time | The quickest delivery time |

| SMD+Connector | 5~200 | 6WD | 3WD |

| 201~2000 | 9WD | 7WD | |

| ≥2000 | 12~15WD | 10WD | |

| SMD+DIP | 5~200 | 6WD | 4WD |

| 201 ~2000 | 12WD | 10WD | |

| ≥2000 | 20WD | 15WD | |

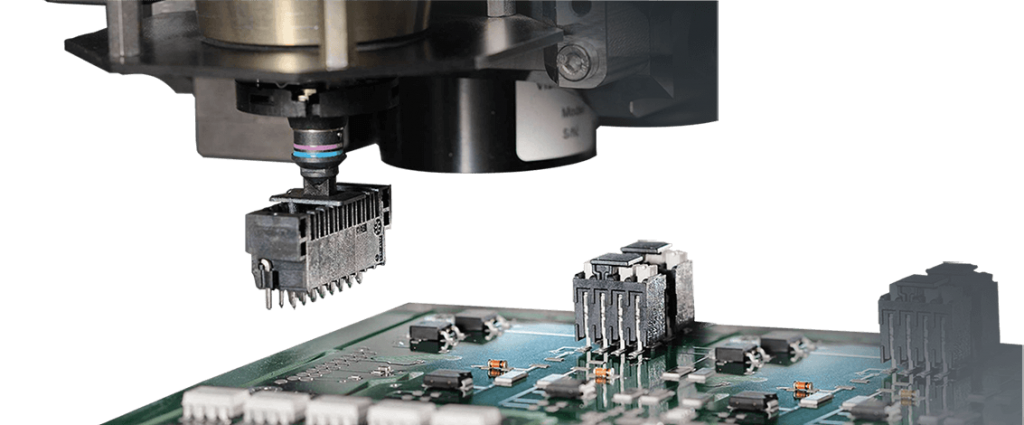

1. Preparation of production materials 2. Making pcb stencil

3. QC inventory materials 4. Program debugging

5. Materials on the machine 6. Printing solder paste

7. First try stickers 8. Patch processing

9. Reflow soldering 10. AOI optical inspection

11. After welding 12. QC test

13. Packaging

Required Data

Choosing the right PCB assembly service is a crucial decision that can significantly impact a business’s production processes and the quality of its end products. Factors such as experience, reliability, reputation, and the range of additional services offered should all be carefully considered.

PCBSky, the industry leader in PCB assembly services, possesses the expertise, facilities, and commitment to excellence necessary to meet the most demanding requirements. With our state-of-the-art facilities, highly skilled technicians, and dedication to quality, we have helped numerous businesses maximize efficiency and deliver exceptional products.

Don’t settle for subpar PCB assembly services. Choose PCBSky as your trusted partner and experience the difference firsthand. Contact us today to discuss your requirements and take your production processes to new heights.

If you have any questions or concerns about PCBSky, please feel free to contact us through Email or hotline.