Are you in search of a Rogers PCB manufacturer? However, you have no idea what it is! Whether you are a skilled or unskilled engineer, this article will guide you through everything you need to know about a Rogers PCB, what it is, the benefits of a Rogers PCB, the features of a Rogers PCB, and lastly, the difference between Rogers and FR4 materials and why should you choose a Rogers PCB.

So, if you want to get all the information of a Rogers PCB, then read ahead!

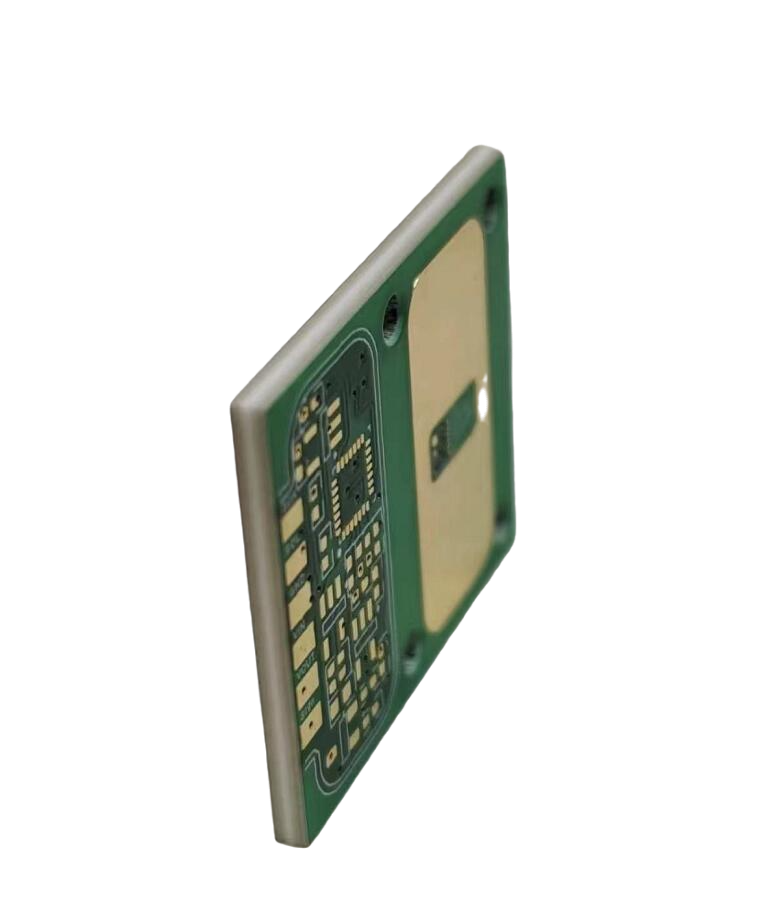

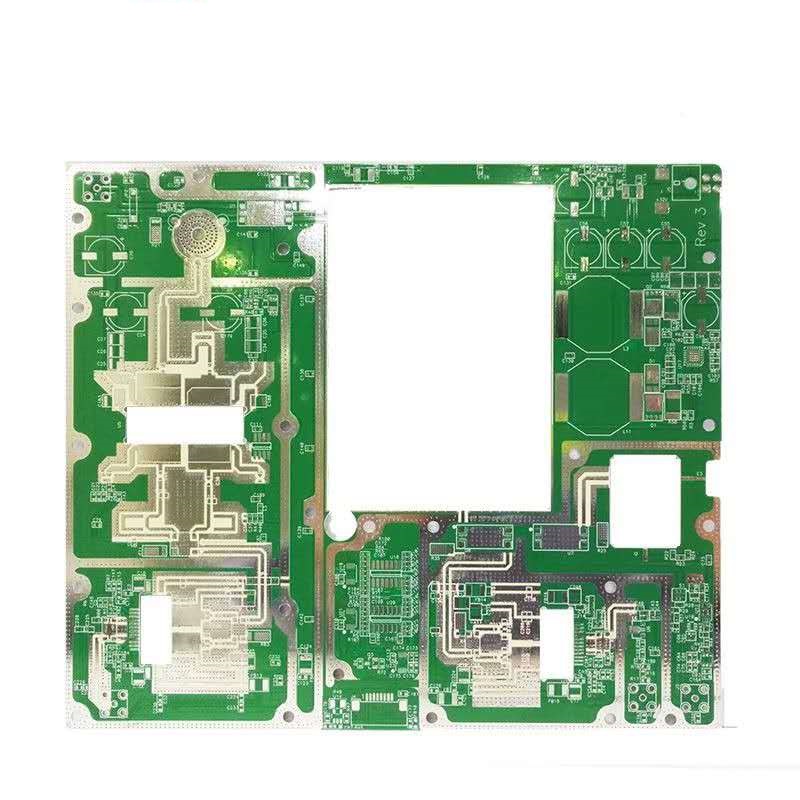

Rogers PCB stands for Rogers Printed Circuit Board. It’s a critical component in many electronic devices, working like a roadmap for electrical connections. These PCBs are not your average boards. They’re made using a special material called Rogers laminate, which offers unique characteristics.

Now, why should you consider using a Rogers PCB? Well, there are several advantages:

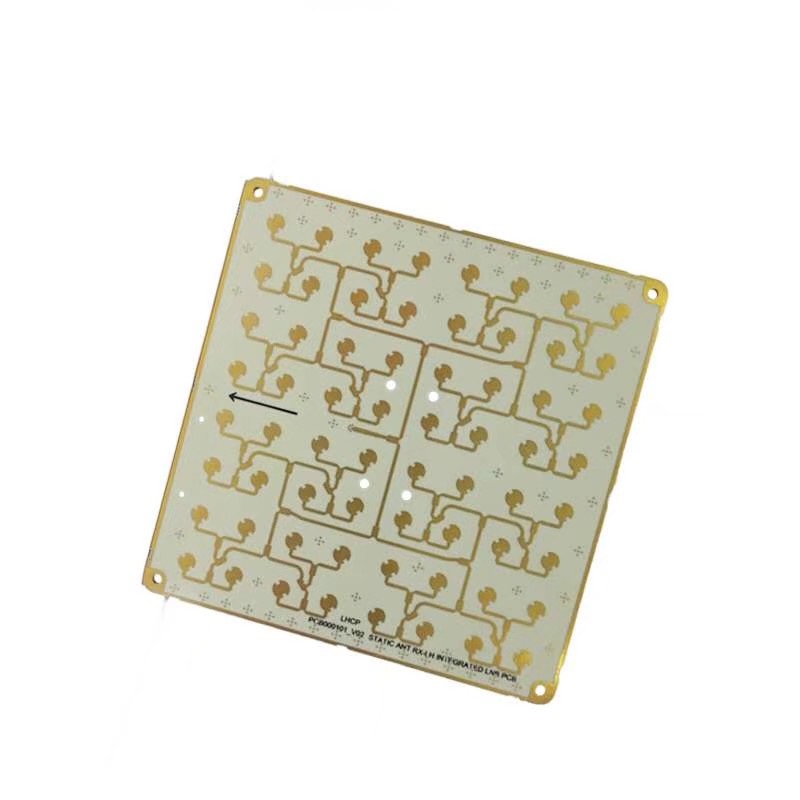

High-Frequency Performance: Rogers PCBs are champions when it comes to working at high frequencies. They maintain stable electrical properties even at high speeds, making them ideal for applications like wireless communication and radar systems.

Low Signal Loss: These PCBs have minimal signal loss, which is a big deal for maintaining the integrity of your electronic signals.

Temperature Resistance: Rogers PCBs can handle extreme temperatures without losing their performance. This is crucial for applications that face temperature variations.

Durability: They’re built to last. Rogers PCBs can withstand harsh environmental conditions and have a longer lifespan compared to some other materials.

Rogers PCBs come with some standout features that set them apart:

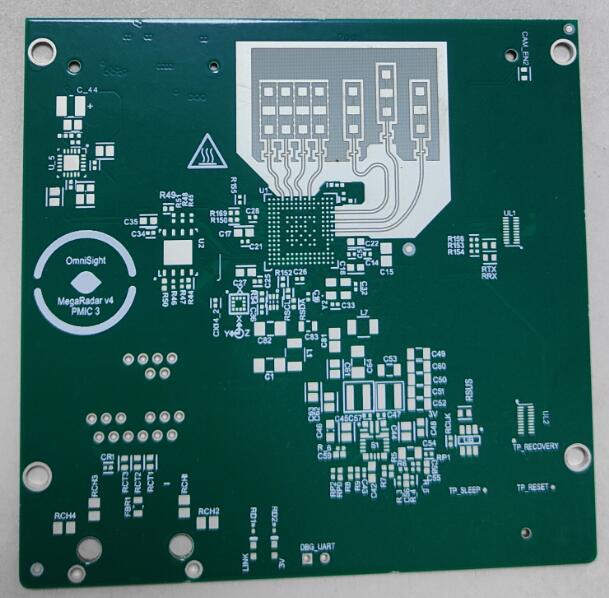

Dielectric Constant (Dk): Rogers laminate materials offer a consistent and precise Dk, ensuring accurate signal propagation.

Low Dissipation Factor (Df): The low Df of Rogers PCBs means less signal loss and higher performance.

Tight Tolerance: These boards are manufactured with tight tolerances, ensuring reliability and consistency in your projects.

Available in Various Thicknesses: Rogers PCBs come in different thicknesses, allowing you to choose the one that best suits your application.

Now, you might wonder how Rogers PCBs compare to the more common FR4 boards.

Rogers PCBs:They use specialized Rogers laminate, which maintains excellent electrical properties even at high frequencies.

FR4 Boards: FR4 boards use a standard fiberglass substrate suitable for applications with lower-frequency needs.

Rogers PCBs: Ideal for high-frequency applications, like wireless communication and radar systems, ensuring accurate signal propagation.

FR4 Boards: Reliable but not as well-suited for high-frequency designs, making them cost-effective for less demanding applications.

Rogers PCBs: Often pricier due to exceptional performance characteristics, justified for high-frequency applications.

FR4 Boards: Cost-effective and budget-friendly, making them a practical choice for various applications without specific high-frequency demands.

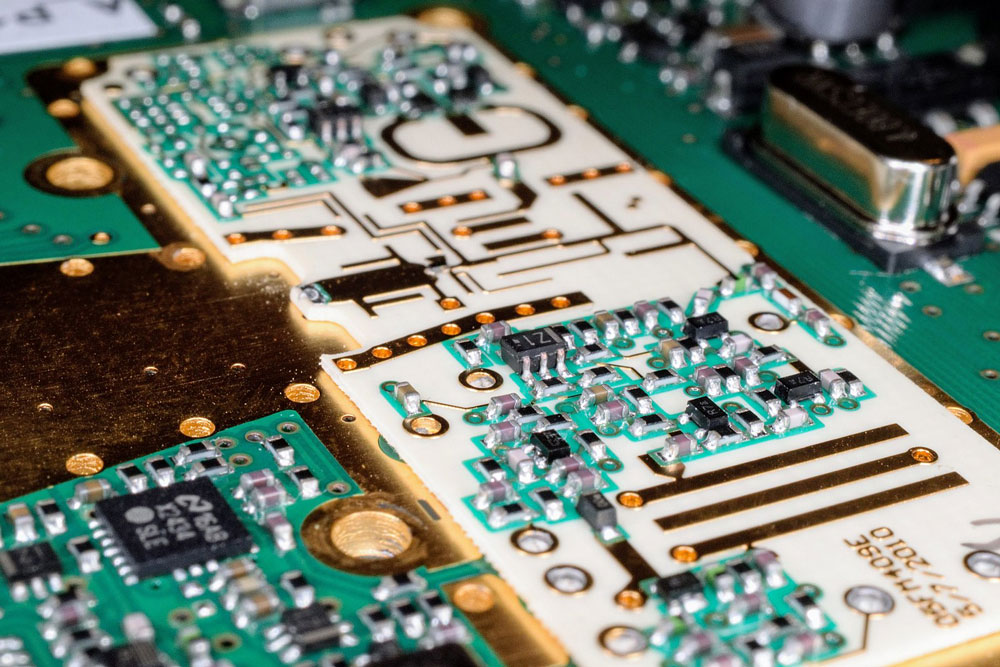

Designing a Rogers PCB is a process that demands precision and expertise. It all begins with the selection of the appropriate Rogers laminate material, considering the specific application’s requirements for frequency, signal integrity, and temperature tolerance. Engineers must carefully plan the board layout, ensuring that traces, vias, and components are strategically

placed to optimize signal performance and minimize signal loss. The dielectric constant (Dk) and dissipation factor (Df) of the Rogers material must be factored into the design to guarantee accurate signal propagation.

Additionally, tight tolerances are essential to achieve the desired reliability and consistency. Successful Rogers PCB design requires a deep understanding of the material’s properties and a keen eye for detail, making it a critical step in achieving the exceptional benefits that Rogers PCBs offer.

Rogers PCBs are versatile and essential components in a wide range of advanced technologies and industries.

5G Communication: Rogers PCBs power the lightning-fast 5G networks, ensuring that your phone and devices can communicate quickly and without losing important data.

Satellite Communication: These PCBs are crucial for keeping satellites connected in space, allowing them to send and receive signals reliably.

Aerospace Technology: In airplanes and helicopters, Rogers PCBs maintain the performance of critical systems, even in extreme temperatures and challenging conditions.

Medical Equipment: Hospitals rely on Rogers PCBs for diagnostic machines, ensuring precise and reliable health check-ups.

Automotive Technology: In the automotive industry, these PCBs are used for vehicle radar systems, infotainment, safety features, and other advanced technologies.

Military and Defense: Rogers PCBs are a trusted choice for military applications, where

top-notch performance and durability are non-negotiable, helping maintain national security.

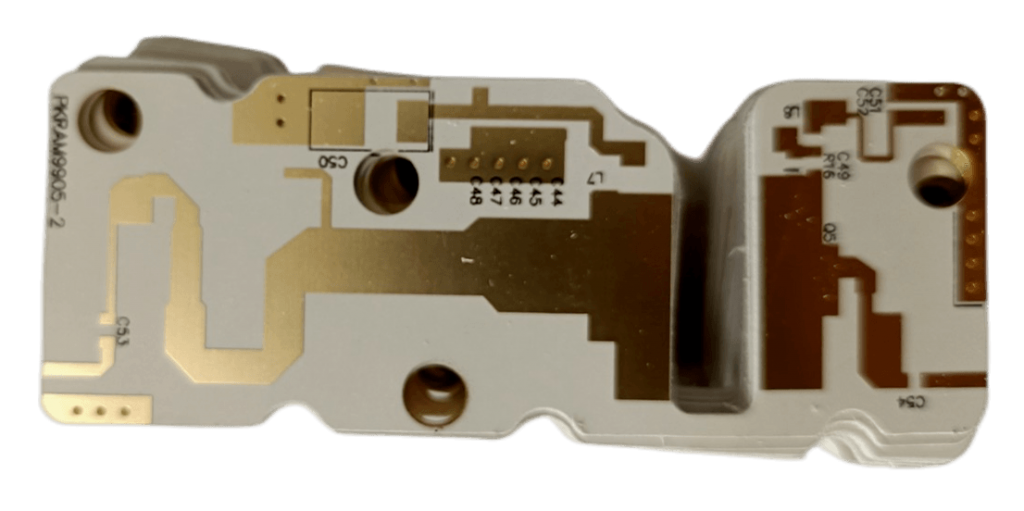

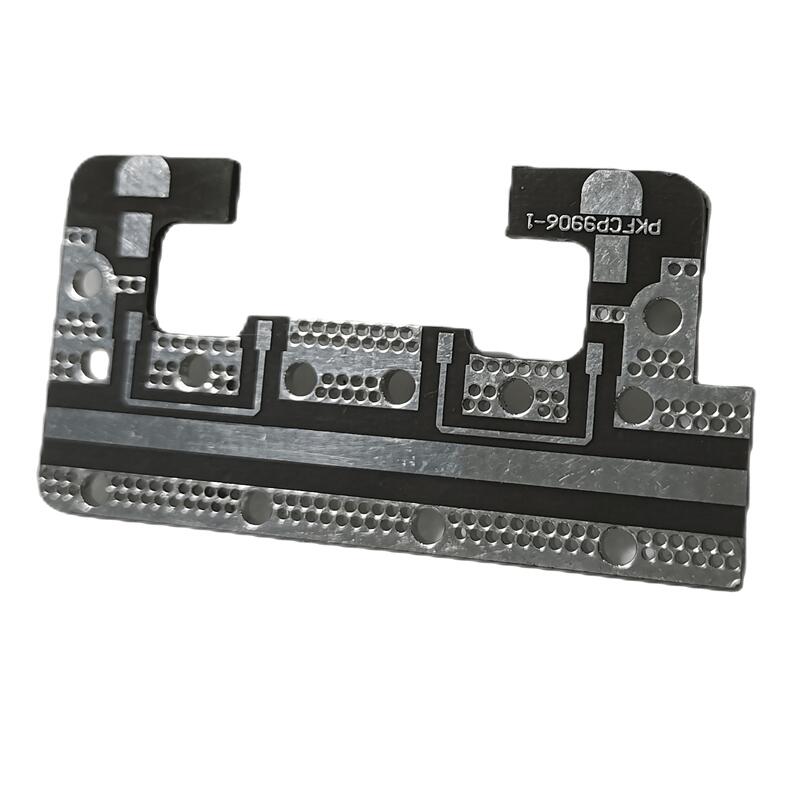

Rigid Flexible PCBs, and PCB Prototypes are different categories or characteristics of printed circuit boards that can be made from various materials, including Rogers laminates.

Rogers PCBs refer to printed circuit boards made using Rogers Corporation’s high-performance materials, which are known for their excellent electrical properties, particularly at high frequencies. Rogers PCBs can be either rigid or flexible, depending on the specific Rogers laminate used and the design requirements.

Rigid-flex PCBs are PCBs that combine both rigid and flexible sections on the same board. Again, these can use various materials, and Rogers laminates might be chosen if the application requires high-frequency performance.

PCB Prototypes are not a specific type of PCB but rather early-stage boards created to test and refine a design before mass production. PCB prototypes can be made from a variety of materials, including Rogers laminates, if the design necessitates it.

Rogers materials are known for their electrical performance advantages. Still, they can be used in a variety of PCB types, including rigid-flex, and prototypes, depending on the specific project requirements.

So, why should you choose a Rogers PCB? If your project demands high-frequency performance, minimal signal loss, and reliability under extreme conditions, then a Rogers PCB is the way to go. While they might cost a bit more than FR4, the advantages they bring can be well worth the investment.

In conclusion, a Rogers PCB is a specialized circuit board with remarkable characteristics, ideal for high-performance electronics. Whether you’re working on a cutting-edge communication system or a weather-resistant device, Rogers PCBs have the qualities to ensure your project’s success.

If you’re considering Rogers PCBs for your project, look no further than PCB Sky. PCB Sky is an ISO 9001:2008, IATF 16949, ISO 13485, UL, and SGS-certified high-technology custom Printed Circuit Boards manufacturer in China. With our commitment to providing you with quality and cutting-edge technology, PCBSky is your trusted partner for Rogers PCB solutions.

Lots of customers come to buy Rogers PCB. We keep All types Rogers material in stock, if you need any of them, welcome to contact us for the price.