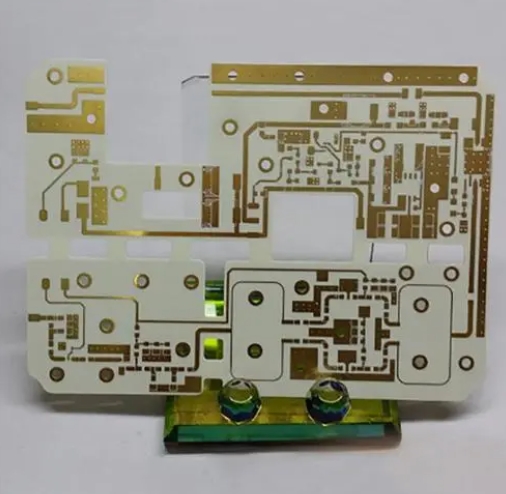

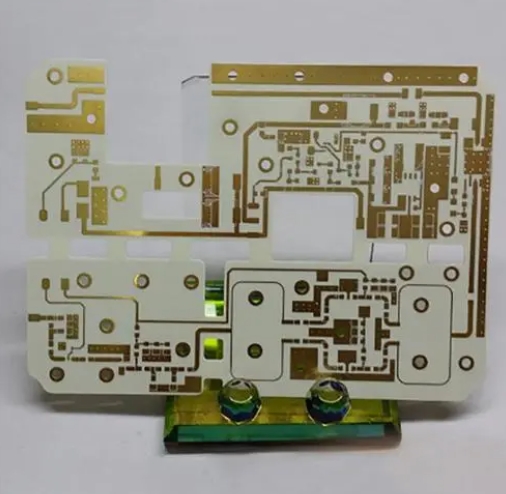

Wiring high frequency PCBs requires careful consideration of signal integrity, impedance matching, and minimizing electromagnetic interference (EMI). Here’s a practical guide to wiring high-frequency PCBs:

- Layer Stack-up:

- Choose a layer stack-up that minimizes signal losses and provides controlled impedance. Typically, high-frequency PCBs have dedicated signal layers and ground planes to manage return paths effectively.

- Impedance Control:

- Maintain controlled impedance for signal traces by using specialized PCB materials and precise trace width and spacing. Impedance calculators and simulation tools can help with this.

- Transmission Lines:

- Use transmission lines, like microstrips or striplines, for routing high-frequency signals. Proper termination and matched impedance are essential to minimize signal reflections.

- Grounding:

- Implement a solid, low-impedance ground plane to provide a stable reference plane for signals. Avoid routing signals over splits in the ground plane.

- Signal Integrity:

- Minimize signal skew and maintain signal integrity by ensuring that traces are of equal length. Differential pairs should be routed together to maintain their relative spacing.

- Avoid 90-Degree Bends:

- Sharp corners and 90-degree bends can lead to signal degradation and EMI. Use 45-degree bends or curved traces instead.

- Differential Pair Routing:

- Route high-speed differential pairs closely together with consistent spacing to maintain controlled impedance.

- Spacing and Clearance:

- Maintain adequate spacing and clearance between traces to prevent crosstalk and interference. Follow manufacturer guidelines for minimum spacing.

- Signal Return Paths:

- Ensure that the return paths for signals are as close as possible to the signal trace to minimize loop area. Avoid vias in high-frequency signal paths when possible.

- Via Placement:

- Use microvias or blind vias for layer transitions, and minimize the use of through-hole vias. Proper via placement helps reduce signal discontinuities.

- Ground Stitching Vias:

- Add ground stitching vias around high-frequency components to connect the local ground plane to the main ground plane. This reduces ground loops and improves signal quality.

- Component Placement:

- Place high-frequency components close to each other and minimize the distance between them and the connector or source. This reduces parasitic capacitance and inductance.

- Power Distribution:

- Design a clean and low-noise power distribution network. Isolate power domains and use dedicated power and ground planes for different components.

- Shielding:

- Consider adding shielding cans or enclosures for sensitive components to prevent EMI and RF interference.

- Simulation and Analysis:

- Use simulation tools and impedance analyzers to validate your high-frequency design. This helps identify and address signal integrity issues.

- Testing and Validation:

- After PCB fabrication, perform high-frequency testing, such as vector network analysis (VNA) and time-domain reflectometry (TDR), to ensure that the PCB meets design specifications.

- Document Everything:

- Keep detailed documentation of the PCB design, including materials used, trace widths, impedance values, and routing guidelines for future reference.

Designing high-frequency PCBs is a complex task that requires a deep understanding of electromagnetic principles and careful attention to detail. Following these guidelines and seeking expert advice, when needed, will help ensure the successful design and performance of your high-frequency PCBs.