Are you searching for the perfect manufacturer for PTFE Teflon PCBs? Look no further. In this comprehensive guide, we will unveil the secrets of PTFE Teflon PCBs and help you choose the right manufacturer for your needs. Whether you are a tech enthusiast exploring new possibilities or a seasoned electronic engineer looking to upgrade your projects, this article will provide you with valuable insights to make an informed decision.

Our brand’s voice is one that is knowledgeable, reliable, and trustworthy. As experts in the field, we understand the importance of finding the right manufacturer for PTFE Teflon PCBs, as it directly impacts the quality and performance of your electronic devices. That’s why we have crafted this guide to provide you with all the information you need to choose wisely. From understanding the benefits of PTFE Teflon PCBs to assessing the capabilities and experience of manufacturers, we leave no stone unturned in helping you make the best choice. So, let’s dive in and uncover the secrets of PTFE Teflon PCBs together.

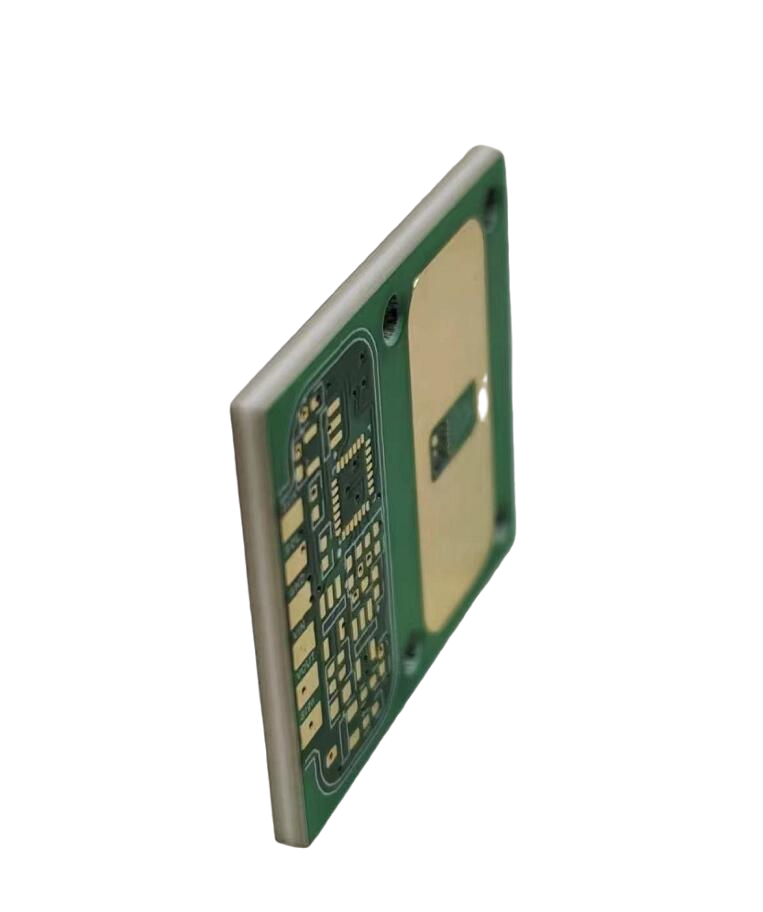

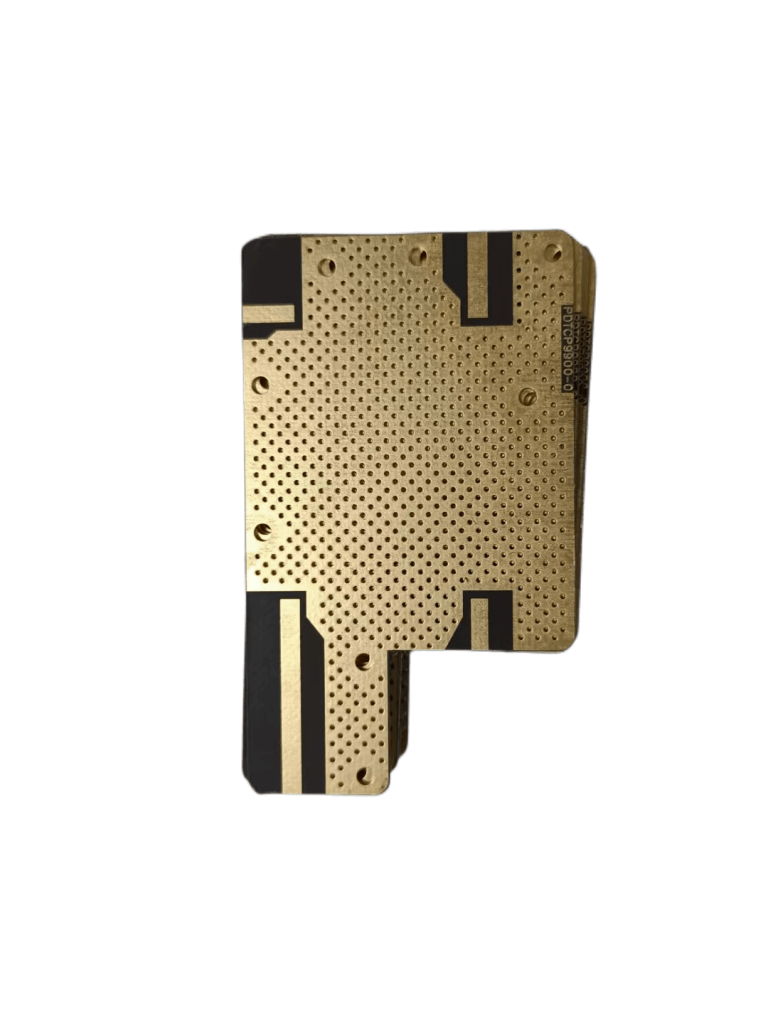

PTFE Teflon PCBs are circuit boards that use Teflon as the base material. Teflon, also known as polytetrafluoroethylene (PTFE), is a synthetic polymer that is known for its low coefficient of friction, non-stick properties, and resistance to heat and chemicals. These properties make it an ideal material for use in PCBs, particularly in applications where high temperatures, harsh chemicals, or corrosive environments are present.

PTFE Teflon PCBs are widely used in industries such as aerospace, defense, telecommunications, and medical equipment. They are also used in applications such as high-frequency communication systems, microwave circuits, and power amplifiers. PTFE PCBs offer several advantages over traditional PCBs, which we will discuss in the next section.

PTFE Teflon PCBs offer several advantages over traditional PCBs. Firstly, they have a low dielectric constant, which means that they can transmit signals faster and with less distortion. This makes them ideal for high-frequency applications such as radar systems and satellite communication. Secondly, Teflon PCBs have a high thermal stability, which means that they can withstand high temperatures without degrading. This makes them ideal for use in harsh environments such as aerospace and defense applications. Finally, PTFE PCBs are resistant to chemicals and moisture, which makes them ideal for use in medical equipment and other applications where cleanliness and sterility are important.

PTFE Teflon PCB is used in a wide range of applications, including:

Aerospace and defense: PTFE PCBs are used in radar systems, avionics, and communication systems for their high frequency and thermal stability.

Telecommunications: Teflon PCBs are used in base stations, antennas, and microwave communication systems for their high frequency and low signal loss.

Medical equipment: PTFE PCBs are used in medical equipment such as MRI machines and pacemakers for their resistance to chemicals and moisture.

Industrial automation: PTFE PCBs are used in industrial automation systems for their resistance to harsh chemicals and high temperatures.

Power amplifiers: Teflon PCBs are used in power amplifiers for their high thermal stability and low signal loss.

Choosing the right manufacturer for your Teflon PCBs is crucial to ensuring the quality and reliability of your electronic devices. Here are some factors to consider when choosing a Teflon PCB manufacturer:

Quality control and certifications in Teflon PCB manufacturing

Quality control is essential in Teflon PCB manufacturing to ensure that the PCBs meet the required specifications and standards. Look for manufacturers that have a robust quality control system in place, such as ISO 9001 certification. This certification ensures that the manufacturer has implemented a quality management system that meets international standards.

Understanding the manufacturing process of Teflon PCBs

It is essential to choose a manufacturer that has a deep understanding of the manufacturing process of Teflon PCBs. The manufacturer should be able to provide you with detailed information on the manufacturing process, from material selection to final testing. This will help you understand the quality of the PCBs and ensure that they meet your requirements.

At PCBSky, we understand the intricacies of PTFE PCB manufacturing. Our state-of-the-art facilities and rigorous quality control processes ensure that every PTFE PCB that leaves our facility meets the highest standards of quality and reliability. With our expertise, we can customize PTFE PCBs to meet your specific requirements, providing you with a solution that perfectly aligns with your project needs.

Evaluating the capabilities and expertise of Teflon PCB manufacturers

When choosing a Teflon PCB manufacturer, it is important to evaluate their capabilities and expertise in the field. Look for manufacturers that have experience in manufacturing Teflon PCBs and have a track record of delivering high-quality PCBs. The manufacturer should be able to provide you with references and case studies that demonstrate their expertise in the field.

Cost considerations when selecting a Teflon PCB manufacturer

Cost is an important factor to consider when selecting a Teflon PCB manufacturer. However, it should not be the only factor. Look for manufacturers that offer competitive pricing without compromising on quality. It is also important to consider the long-term costs of using Teflon PCBs, such as maintenance and repair costs.

Here are some success stories of businesses that have used Teflon PCBs:

NASA

NASA uses Teflon PCBs in its spacecraft for their high thermal stability and resistance to radiation. Teflon PCBs are used in critical systems such as communication, navigation, and power management.

Medical equipment manufacturers

Medical equipment manufacturers use Teflon PCBs in their devices for their resistance to chemicals and moisture. Teflon PCBs are used in devices such as pacemakers, defibrillators, and MRI machines.

Telecommunications companies

Telecommunications companies use Teflon PCBs in their base stations and antennas for their high frequency and low signal loss. Teflon PCBs are used in 5G networks to transmit signals at high speeds.

In conclusion, choosing the right Teflon PCB manufacturer is crucial to ensuring the quality and reliability of your electronic devices. Consider factors such as quality control, manufacturing process, expertise, and cost when selecting a manufacturer. Teflon PCBs offer several advantages over traditional PCBs, including low dielectric constant, high thermal stability, and resistance to chemicals and moisture. They are used in a wide range of applications, from aerospace and defense to medical equipment and telecommunications. We hope that this guide has provided you with valuable insights into Teflon PCBs and how to choose the right manufacturer for your needs.

PTFE PCBs offer a range of exceptional benefits and find extensive applications in various industries. Their unique combination of properties makes them a preferred choice for high-performance and demanding electronic systems. Understanding the manufacturing process and the advantages they bring can help engineers and designers harness the full potential of PTFE PCBs. With PCBSky’s expertise and commitment to quality, you can trust us to deliver top-notch PTFE PCB solutions tailored to your specific needs.

At PCBSky, we pride ourselves on being a leading provider of PTFE PCB solutions, offering exceptional quality and service. Our experienced team of engineers and technicians are well-versed in the intricacies of PTFE PCB manufacturing, ensuring that our customers receive top-of-the-line products that meet their exact specifications.

In conclusion, PTFE PCBs offer a multitude of benefits and find extensive applications in various industries. With PCBSky as your partner, you can harness the power of PTFE PCBs to drive innovation and achieve superior performance in your electronic systems. Contact us today to discuss your PTFE PCB requirements and experience the excellence that PCBSky brings to every project.