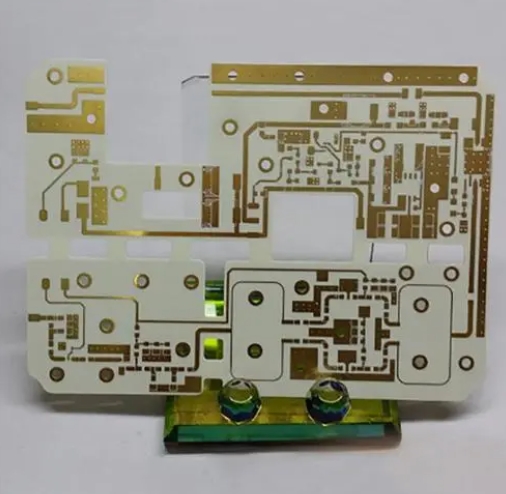

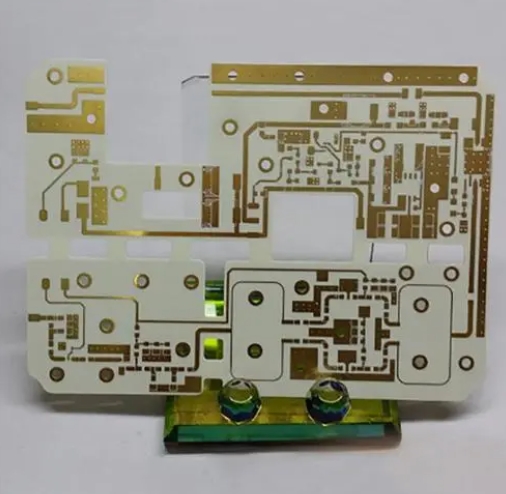

Rogers 4350B is a high-performance printed circuit board (PCB) material known for its exceptional electrical and thermal properties. Here’s an introduction to Rogers 4350B PCB:

Rogers 4350B PCB Material:

- Dielectric Material: Rogers 4350B is a high-frequency laminate material that features a ceramic-filled hydrocarbon thermoset resin system. This dielectric material is engineered for high-frequency applications, particularly in RF (radio frequency) and microwave circuits.

Key Features and Characteristics:

- Low Loss: Rogers PCB material offers excellent dielectric properties, including a low dissipation factor (Df), which results in minimal signal loss and high signal integrity, making it suitable for high-frequency applications.

- High Thermal Conductivity: It has a high thermal conductivity, which aids in efficient heat dissipation, an important feature for power amplifier applications and components with elevated operating temperatures.

- Dimensional Stability: The material exhibits exceptional dimensional stability, ensuring that the PCB maintains its shape and integrity even in demanding environments.

- Copper Clad Laminates: Rogers 4350B is available as copper clad laminates, which simplifies PCB manufacturing and assembly.

- Compatibility: It is compatible with various fabrication methods, including multi-layer constructions, surface mount technology (SMT), and mixed-signal designs.

Applications:

Rogers 4350B PCB material is widely used in applications that require high-frequency performance and low signal loss, including:

- RF and microwave circuits

- Antennas and phased-array radar systems

- High-frequency telecommunications equipment

- Aerospace and defense electronics

- Medical devices and equipment

- Automotive radar systems

- Satellite communication systems

Benefits:

- High-frequency performance: Rogers 4350B excels at supporting high-frequency signals with minimal loss, making it an excellent choice for critical RF applications.

- Thermal management: Its high thermal conductivity assists in efficient heat dissipation, ideal for power amplifiers and other high-heat applications.

- Durability and stability: The material’s exceptional dimensional stability ensures the reliability and long-term performance of the PCB.

Rogers 4350B PCBs are favored in industries where high-frequency signals, low loss, and thermal management are essential. Designers and engineers choose this material to achieve optimal performance and reliability in their electronic systems, particularly those operating in demanding RF and microwave environments.

Dimensional Stability

It is a property necessary for the construction of mixed dielectric multilayer PCB boards. The low CTE of RO4350 laminates on the Z-axis provides reliable through hole quality even in severe thermal shock applications. The material of the RO4350 series has a TG of more than 280 ° C (536 ° F), so its expansion properties remain stable at all process temperatures in the circuit. RO4350 Series laminates can be easily converted into printed circuit boards using standard FR4 circuit board processing techniques. Unlike high-performance PTFE-based materials, RO4350 series laminates do not require special preparation processes such as sodium etching. This material is a rigid, heat-stable laminate that can be treated with automated handling systems and washers used to make the copper surface.

Availability

RO4350 laminates are currently available in a variety of 1080 and 1674 glass fabric models, all of which meet the same laminated electrical performance specifications. Designed specifically for direct replacement of RO4350 material, RO4350 laminates use RoHS compliant flame retardant technology for applications requiring UL 94V-0 certification. These materials meet the requirements of IPC-4103/10 single sheets for RO4003C and /11for RO4350.

Rogers PCB Production Guidelines

RO4350 high-frequency circuit materials have been developed to provide high-frequency performance comparable to woven PTFE glass substrates, which simplifies fabrication with epoxy/glass laminates. RO4350 is a thermoset material filled with hydrocarbon/glass reinforced ceramic with a very high glass transition temperature (TG> 280 ° C). Unlike PTFE-based microwave materials, no special treatment or via is required. As a result, the processing and assembly costs of the RO4350 material circuit are comparable to those of the epoxy/glass laminates.

Here are some basic tips for dealing with RO4350 double-sided plates. In general, the parameters and treatment methods used for epoxy/glass plates can be used to treat RO4350 plates.

Input / Output Rogers PCB Material

Inlet and outlet materials must be flat and rigid to minimize copper burrs. Recommended input materials are aluminum and rigid composite panels (0.254 to 0.635 mm). Most conventional starting materials with or without an aluminum coating are suitable.

Maximum Height of The Battery

The thickness of the material to be drilled must not exceed 70% of the groove length. This includes the thickness of the input material and penetration into the substrate.

Perforation

Surface speeds of more than 500 SFM and chip load less than 0.05mm (0.002″) should be avoided as much as possible.