I believe that many people are not new to PCB circuit boards. They may be heard frequently in daily life, but they may not know much about PCBA, and may even be confused with PCB. So what is PCB? How did PCBA evolve? What is the difference between PCB and PCBA? Let’s take a closer look.

PCB is the abbreviation of Printed Circuit Board. Because it is made by electronic printing, it is called “printed” circuit board. PCB is an important electronic component in the electronics industry, a support for electronic components, and a carrier for the electrical connection of electronic components. PCB has been widely used in the manufacture of electronic products. The unique characteristics of PCBs are summarized as follows:

1. High wiring density, small size and light weight, which is conducive to miniaturization of electronic equipment.

2. Due to the repeatability and consistency of the graphics, errors in wiring and assembly are reduced, and the time for equipment maintenance, debugging and inspection is saved.

3. It is beneficial to mechanized and automated production, which improves labor productivity and reduces the cost of electronic equipment.

4. The design can be standardized to facilitate interchange.

PCBA is the abbreviation of Printed Circuit Board + Assembly, which means that PCBA is the whole process of PCB empty board SMT and then DIP plug-in.

Note: SMT and DIP are both ways to integrate parts on the PCB. The main difference is that SMT does not need to drill holes on the PCB. In DIP, the PIN pin of the part needs to be inserted into the drilled hole.

SMT (Surface Mounted Technology) surface mount technology, mainly use the placement machine to mount some micro parts on the PCB board, its production process is: PCB board positioning, printing solder paste, placement machine placement, over-reflow Furnace and finished inspection.

DIP is “plug-in”, that is, inserting parts on the PCB version. These are some parts that are larger in size and are not suitable for the integration of parts in the form of plug-ins when they are used in placement technology. Its main production processes are: adhesive backing, plug-in, inspection, wave soldering, plate printing and finished inspection.

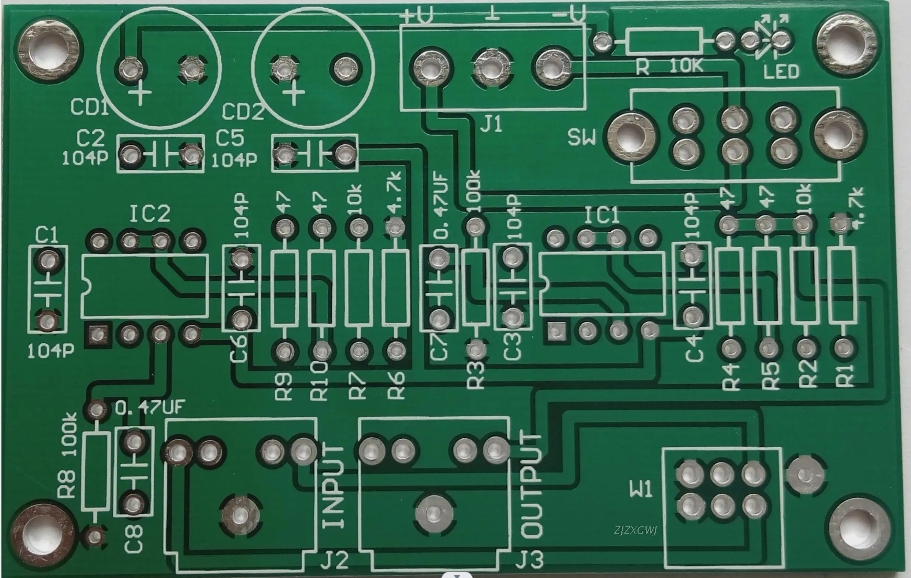

As can be seen from the above introduction, PCB’A refers to a processing process, which can also be understood as a finished circuit board, and PCB’A can only be counted after the processes on the PCB board are completed. The PCB refers to an empty printed circuit board with no parts on it.

In summary: PCBA is the finished board; PCB is the bare board.