Oxidation affects all thermoset laminate materials over time and temperature, including FR-4. In the long term, oxidation can lead to small increases in dielectric constant and dissipation factor of the circuit substrate. The rate of change and impact on circuit performance depends on design and operating temperature. For applications demanding greater stability at elevated temperatures Rogers has developed RO4835™ laminate, that is signifi cantly more resistant to oxidation than other hydrocarbon based materials.* Moreover, RO4835 material provides nearly identical electrical and mechanical properties to RO4350B™ laminates, which customers have used successfully for many years. As part of the RO4000® hydrocarbon ceramic laminate family, RO4835 laminates are designed to offer superior high frequency performance and low-cost circuit fabrication. The result is

a low loss material which can be fabricated using standard epoxy/glass (FR-4) processes offered at a competitive price.

The selection of laminates typically available to designers is signify cantily reduced once operational frequencies increase to 500 MHz and above. RO4000® material possesses the properties needed by designers of RF microwave circuits and matching networks and controlled impedance transmission lines. Low dielectric loss allows RO4000 series material to be used in many applications where higher operating frequencies limit the use of conventional circuit board laminates. RO4000 material’s thermal coeffi cient of expansion (CTE) provides several key benefi ts to the circuit designer. The expansion coeffi cient of RO4000 material is similar to that of copper which allows the material to exhibit excellent dimensional stability, a property needed for mixed dielectric multi-layer board constructions. The low Z-axis CTE of RO4000 laminates provides reliable plated

through-hole quality, even in severe thermal shock applications. RO4000 series material has a Tg of >280°C (536°F) so its expansion characteristics remain stable over the entire range of circuit processing temperatures.

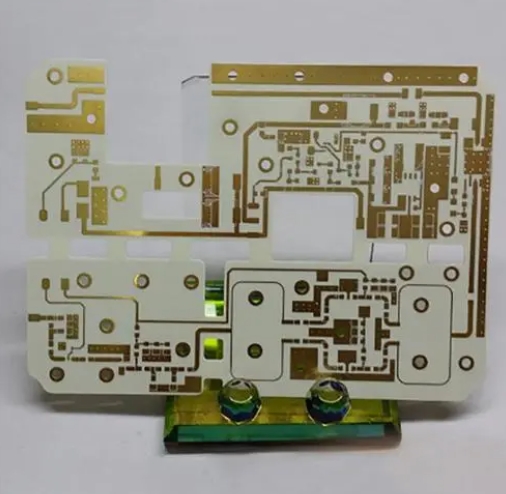

RO4000 series laminates can easily be fabricated into printed circuit boards using standard FR-4 circuit board processing techniques. Unlike PTFE based high performance materials, RO4000 series laminates do not require specialized via preparation processes such as sodium etch. This material is a rigid, thermoset laminate that is capable of being processed by automated handling systems and scrubbing equipment used for copper surface preparation. RO4835 laminates utilize RoHS compliant fl ame-retardant technology for applications requiring UL 94V-0 certify cation.The dielectric constant of Rogers 4835 was 3.48 ± 0.05

Main advantages

Compared with the traditional thermosetting materials, its oxidation resistance is increased by 10 times.

Excellent electrical performance enables higher frequency applications.

No bubbles or delamination

Reliable through-hole plating

It is stable in the whole circuit processing temperature range.

Rogers 4835 PCB typical applications

Automotive radar and sensors

Point to point microwave transmission.

Power amplifier

Phased array radar.

RF moduleLots of customers come to buy

Rogers PCB. We keep All types of Rogers material in stock, if you need any of them, welcome to contact us for the price and datasheet.