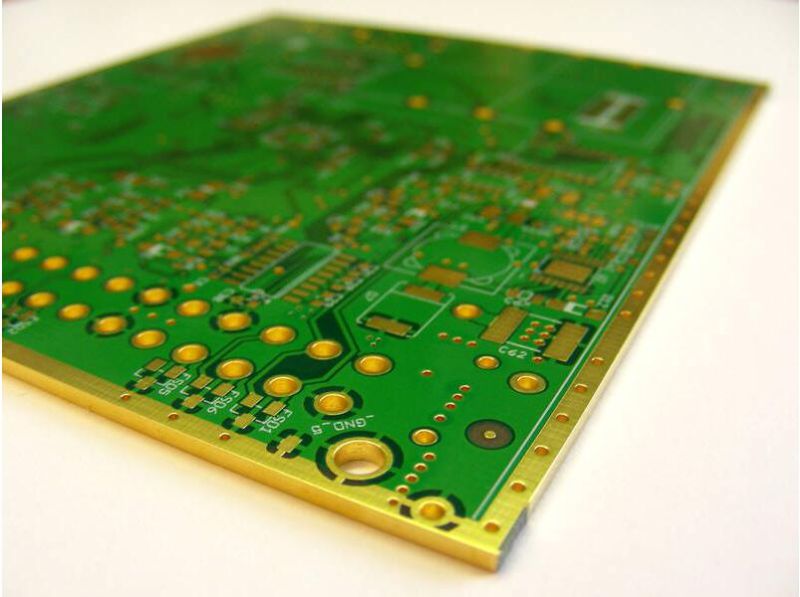

Edge plating is the process of plating a thin layer of copper and other metals on the sides of the PCB board according to the principle of electrolysis. The process of attaching a layer of metal film to the surface of metal or other material parts by electrolysis realizes that the side of the PCB can also conduct electricity and improves the appearance.

Edge plating requires a low-voltage high-current power supply to the edge plating tank and an electrolysis device composed of the edge plating solution and parts to be plated (cathode and anode). The composition of the edge plating solution is different depending on the plating layer, but they all contain a main salt that provides metal ions, a complexing agent that can complex the metal ion in the main salt to form a complex, a buffer used to stabilize the pH of the solution, an anode activator, and special additives (such as brightener, grain refiner, leveling agent, wetting agent, stress relief agent and fog inhibitor, etc.). The edge plating process is a process in which metal ions in the plating solution are reduced to metal atoms by electrode reaction under the action of an external electric field, and metal deposition is performed on the cathode. Therefore, this is a metal electrodeposition process that includes liquid phase mass transfer, electrochemical reaction, and electro crystallization.