In the era of Internet of things driven by 5g, the market demand of HDI and R-F PCB is growing. However, with more and more manufacturers entering the field, the fierce competition leads to the rampant low-price strategy, and the profit space of the head manufacturers is constantly compressed, which leads to the decline of profitability, and the giant manufacturers are forced to leave the market.

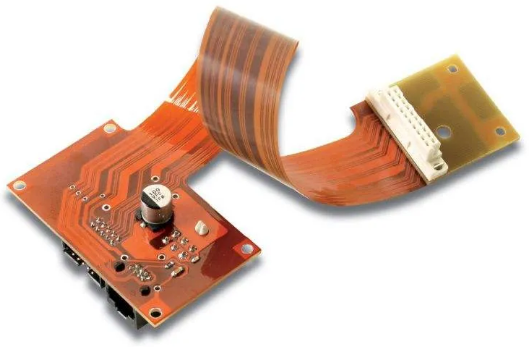

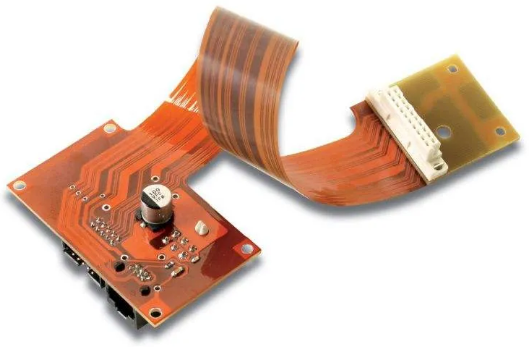

In contrast, the types of consumer electronics are becoming more and more diversified, and the demand for subdivided application fields is growing. Chinese PCB manufacturers also see opportunities in the layout. With the increasing import rate of rigid flexible PCB in electronic products, PCB industry continues to pay more attention to it. In the past, rigid flexible PCB was mostly used in the field of mobile phone battery, but now, with the emergence of new applications such as lens module, display module, TWS Bluetooth headset and wearable device, more and more enterprises are willing to invest in

PCB manufacturing rigid flexible PCB.

Penetration rate of consumer electronic products continues to increase.

Rigid flex PCB was first used in the field of battery module. Now looking at all mobile phone brands in the world, it is a consensus that rigid flex PCB is used for batteries, and it may become a long-term trend. At the same time, in order to accommodate more and more lenses in smaller and smaller space, mobile phone lens module also began to use rigid flexible PCB. At present, both Korean and Chinese brand mobile phones use rigid flexible PCB as the mainstream technology of lens. In addition, it is gradually expanded to display and other mobile phone modules. As for the next application of flexible PCB, it is expected to become a natural wearable device.

It is understood that in addition to the fact that Apple has gradually changed the rigid flexible PCB of Apple watch and air pods series products into the design scheme of flexible board plus sip, Korean and Chinese brands still mostly use rigid flexible PCB as the main technology of wearable devices. In addition to major technology companies, SPORTS BRACELET products are mainly made of rigid flexible PCB. As for TWS charging box, rigid flexible PCB is mostly used. The earphone part depends on product specifications and customer design orientation.

In the future, the chance to see rigid flexible PCB on other consumer electronic products will only be higher and higher. Some industry insiders disclosed that what they see now, including smart audio and other smart home appliances and other Internet of thing’s products, may adopt rigid flexible PCB in specific functional modules due to their design and cost requirements.

The key technology of rigid flexible PCB for automobile market.

The position of rigid flexible PCB in automotive electronics is rising, which is beyond the original imagination of PCB industry. The main reason is that we didn’t expect the technology used in mobile phone lens module at the beginning to extend to automotive ADAS lens module, and further attract automotive parts manufacturers to import rigid flexible PCB into Guangda and other module products, and transform into the entry brick of high-level automotive market.

With cost advantage and design flexibility, there is a large space for future development.

Reviewing the technical characteristics of rigid flexible PCB, the industry believes that rigid flexible PCB is just in the middle of design flexibility and cost advantage, so it has become the design preference of many terminal brands. For example, in addition to the mobile phone battery and lens, Korean manufacturers import rigid flexible PCB into the display and multiple mobile phone modules. According to relevant manufacturers, half of the internal and external modules of Samsung’s recent flagship new note 20 are rigid flexible PCB, with a high proportion of use.

However, not all companies buy this golden mean feature. For example, apple uses higher specification FPC to improve design flexibility. From iPhone to air pods series, they are actively moving away from rigid flexible PCB. However, this is the design preference of various brands after all, which cannot completely determine the future development of rigid flexible PCB.

Especially in the era of Internet of things, diversified product demand means diversity in design scheme. In the light and short trend, if the terminal brand wants to effectively enlarge the product scale, the demand for cost control will also increase. The junction of dual demand is not only a single niche, but a whole piece of promising land. According to the industry, if all kinds of smart products use image sensing function in the future, how big is the market for lens module, and how big is the opportunity for

rigid flexible PCB.