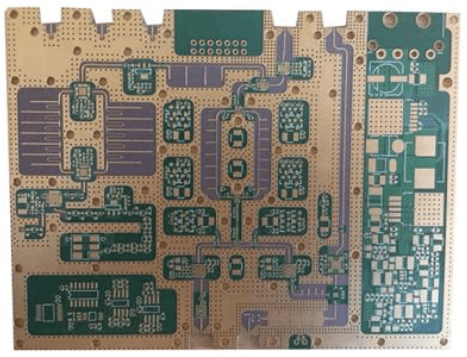

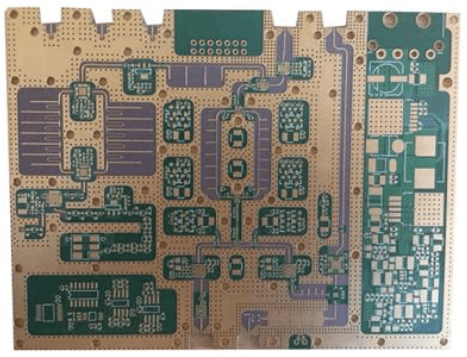

RO3000® high frequency circuit materials are ceramic-filled

PTFE composites intended for use in commercial microwave and RF applications. This family of products was designed to offer exceptional electrical and mechanical stability at competitive prices.RO3000 series laminates are ceramic-filled

PTFE based circuit materials with mechanical properties that are consistent regardless of the dielectric constant selected. This allows the designer to develop multi-layer board designs that use different dielectric constant materials for individual layers, without encountering warpage or reliability problems.

RO3000 materials exhibit a coefficient of thermal expansion (CTE) in the X and Y axis of 17 ppm/°C. This expansion coefficient is matched to that of copper, which allows the

material to exhibit excellent dimensional stability, with typical etch shrinkage (after etch and bake) of less than 0.5 mils per inch. The Z-axis CTE is 24 ppm/°C, which provides exceptional plated through-hole reliability, even in severe thermal environments. The dielectric constant versus temperature for RO3003™ and RO3035™ materials is very stable.

RO3000 series laminates can be fabricated into printed circuit boards using standard

PTFE PCB processing techniques, with minor modifications as described in the application note “Fabrication Guidelines for RO3000Series

High Frequency PCB Materials.

RO3000 series typical applications

Automobile radar

RF coupler

Cost sensitive aerospace and defense applications

GPS antenna

Dielectric Constant

The dielectric constant of RO3003 is 3.00 ± 0.04

The dielectric constant of RO3035 is 3.50 ± 0.05

The dielectric constant of RO3006 is 6.15 ± 0.15

The dielectric constant of RO3010 is 10.2 ± 0.30

Product features:

The dielectric loss factor is only 0.0013;

It can be used in 77GHz high frequency circuit

Temperature characteristics:

Excellent mechanical stability with temperature change

It can be used in high reliability strip line and multilayer circuit structure

It has the same mechanical stability under different dielectric constant

Ideal material for multilayer circuit board design

Suitable for mixed design with epoxy glass multilayer circuit board

Production difficulties

Because PTFE PCB is flexible and prone to crease during manufacturing, it is necessary to handle it with care during production and put it in special vessels; in addition, PTFE PCB needs plasma treatment before PTH process after drilling.

Lots of customers come to buy Rogers PCB. We keep All types of Rogers material in stock, if you need any of them, welcome to contact us for the price and datasheet.