What is a computer PCB?

A computer PCB, or Printed Circuit Board, is a fundamental component of a computer system that serves as a substrate for connecting and interconnecting various electronic components and circuits. It is also sometimes referred to as a computer motherboard or mainboard. Here are the key functions and components typically found on a computer PCB:

- Central Hub: The PCB acts as the central hub or backbone of a computer, providing physical and electrical connections for various essential components.

- CPU Socket: It includes a socket or slot where the Central Processing Unit (CPU), the computer’s primary processor, is installed.

- Memory Slots: These slots accommodate RAM (Random Access Memory) modules, providing volatile memory for the CPU to store and access data.

- Expansion Slots: Typically, there are PCIe (Peripheral Component Interconnect Express) slots that allow users to add expansion cards, such as graphics cards, sound cards, and network cards, to enhance the computer’s capabilities.

- Chipset: The PCB contains a chipset, which is responsible for managing data flow between various components, including the CPU, RAM, and peripherals.

- Storage Interfaces: It provides connectors for storage devices, such as SATA (Serial ATA) or M.2 slots for connecting hard drives and SSDs.

- Power Connectors: There are connectors for the power supply unit (PSU) to deliver electrical power to the motherboard and its components.

- I/O Ports: The PCB includes various input and output (I/O) ports, including USB ports, audio jacks, video outputs, Ethernet ports, and more.

- BIOS/UEFI Chip: A BIOS (Basic Input/Output System) or UEFI (Unified Extensible Firmware Interface) chip stores firmware that initializes and manages hardware during the computer’s startup process.

- Clock Generator: It includes a clock generator to provide timing signals necessary for synchronizing the operation of various components.

- Voltage Regulation: Voltage regulation circuitry is present to ensure stable power delivery to the CPU and other components.

- Connectors and Headers: The PCB has various connectors and headers for connecting case buttons and LEDs, cooling fans, and other peripherals.

The computer PCB is a critical component that facilitates the communication and interaction of all the hardware components within a computer. Its design and features can vary widely depending on the type of computer (e.g., desktop, laptop, server) and its intended use. Computer PCBs are designed to be reliable, durable, and capable of handling the specific needs of the system they are built for.

What circuit boards do computer circuit boards include?

Computer circuit boards, commonly referred to as printed circuit boards (PCBs), can include a variety of different types of circuit boards to perform various functions within a computer system. Here are some of the key circuit boards commonly found in a typical desktop or laptop computer:

- Motherboard (Mainboard): The motherboard is the central circuit board in a computer. It houses the CPU (Central Processing Unit), RAM (Random Access Memory), expansion slots (e.g., PCIe slots for graphics cards and other add-in cards), and connectors for various peripherals. The motherboard is responsible for interconnecting all major components within the computer.

- Graphics Card (GPU): A dedicated graphics card, also known as a GPU (Graphics Processing Unit) card, is responsible for rendering graphics and video in a computer. It’s often plugged into a PCIe slot on the motherboard and includes its own RAM and processing power.

- Sound Card (Audio Card): In some cases, a dedicated sound card can be added to improve audio quality and processing capabilities. Many motherboards come with integrated audio, but dedicated sound cards may offer higher quality audio and more advanced features.

- Network Interface Card (NIC): This circuit board, either integrated into the motherboard or added separately, provides Ethernet or Wi-Fi connectivity, allowing the computer to connect to local networks and the internet.

- Storage Controller: Modern computers typically include storage controllers, often integrated into the motherboard, to manage connections to storage devices such as hard drives and SSDs (Solid-State Drives).

- Memory Modules: While not technically circuit boards, RAM modules are an essential component in a computer. They provide volatile memory for the CPU to work with data and programs.

- Power Supply Unit (PSU): Although not a circuit board, the PSU is a critical component in a computer that converts AC power from the wall outlet into the DC power required by the computer’s components. It’s connected to the motherboard and other components.

- Expansion Cards: These can include additional circuit boards like RAID controllers, USB expansion cards, or specialized hardware for specific tasks.

- I/O Ports and Connectors: While not standalone circuit boards, these are critical parts of the motherboard, providing connections for peripherals such as USB devices, audio jacks, video outputs, and more.

It’s important to note that the specific configuration and components of computer circuit boards can vary widely depending on the type of computer (desktop, laptop, server, etc.) and its intended use. As technology advances, some of these functions may become integrated into the motherboard or other components, leading to smaller and more integrated designs.

What are the design and production difficulties of computer PCBs?

Designing and producing computer PCBs (Printed Circuit Boards) can be a complex and challenging process due to the need for precision, reliability, and compatibility with various components. Here are some of the design and production difficulties associated with computer PCBs:

- Miniaturization: As technology advances, the components on computer PCBs become smaller and more densely packed. Designing and manufacturing PCBs with tiny surface mount components and narrow traces require specialized equipment and expertise.

- Signal Integrity: High-speed data transmission on modern computer PCBs requires careful consideration of signal integrity. Minimizing electromagnetic interference (EMI), controlling impedance, and managing crosstalk are all crucial challenges.

- Thermal Management: Powerful CPUs and GPUs generate a significant amount of heat. Effective thermal management, including the design of heatsinks, heat spreaders, and fan placement, is essential to prevent overheating and ensure long-term reliability.

- Power Delivery: Ensuring stable and efficient power distribution to various components can be challenging. Voltage regulation, power planes, and proper grounding are crucial for reliable operation.

- Layer Stackup: Determining the optimal layer stackup (the arrangement of copper and insulating layers) is critical. A poor stackup design can lead to signal interference, heat buildup, and manufacturing difficulties.

- Complexity: High-performance computers often have complex PCBs with numerous components and interconnections. Managing this complexity while ensuring the PCB meets performance and reliability requirements can be difficult.

- Design for Manufacturability (DFM): PCB designs must be manufacturable at scale. Designers need to consider factors like ease of assembly, component placement, and testing processes to avoid production issues.

- Component Availability: Ensuring that all required components are readily available can be challenging, especially during periods of component shortages or when using specialized or custom components.

- Compliance and Certification: Computer PCBs must meet various industry and safety standards, such as FCC (Federal Communications Commission) regulations and safety certifications. Ensuring compliance adds complexity to the design and testing process.

- Testing and Quality Control: Thorough testing and quality control processes are essential to identify and rectify defects. Testing PCBs for functionality, electrical performance, and reliability can be time-consuming and resource-intensive.

- Cost Management: Balancing performance and cost can be challenging. High-quality materials and advanced manufacturing techniques can drive up production costs, which need to be carefully managed.

- Prototyping: Developing and testing prototypes can be costly and time-consuming, but it is a crucial step in identifying and addressing design issues before mass production.

- Environmental Considerations: Meeting environmental regulations and designing for sustainability can be challenging. Materials selection and end-of-life disposal must be considered.

To address these difficulties, computer PCB designers often collaborate closely with electrical engineers, mechanical engineers, and manufacturing experts. Advanced PCB design software, simulation tools, and testing equipment are also used to optimize designs and ensure reliable performance. Additionally, ongoing research and development in PCB materials and manufacturing techniques help mitigate some of these challenges.

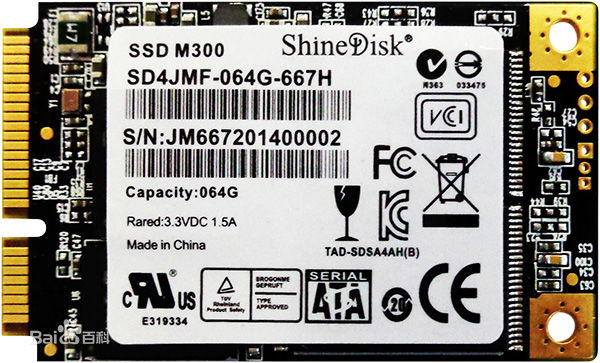

What is a SSD PCB?

A Solid-State Drive PCB (Printed Circuit Board) is the circuit board inside a solid-state drive (SSD) that plays a critical role in the functioning of the SSD. Unlike traditional hard disk drives (HDDs), which have spinning mechanical components, SSDs use NAND flash memory chips to store data, and these chips are mounted on the PCB. Here are the key components and functions of an SSD PCB:

- NAND Flash Memory Chips: The primary storage medium of an SSD is NAND flash memory. These memory chips are mounted on the PCB in various configurations (single-sided or double-sided) and can vary in capacity.

- Controller Chip: The controller chip, often referred to as the SSD controller, is a critical component responsible for managing data storage, addressing memory cells, and ensuring data integrity. It also handles wear-leveling to distribute write and erase cycles evenly across the NAND cells.

- DRAM Cache: Many SSDs include a small amount of DRAM (Dynamic Random-Access Memory) as a cache. The DRAM cache is used for temporary storage of frequently accessed data and metadata to accelerate read and write operations.

- Power Management Circuitry: SSDs typically have power management circuitry to regulate power usage and support features like idle power saving and low-power states.

- Interface Connector: The PCB includes an interface connector that allows the SSD to connect to a computer or other device. Common interface types include SATA (Serial ATA), NVMe (Non-Volatile Memory Express), and M.2 (formerly known as NGFF).

- Firmware: SSDs have firmware embedded in the controller chip, which governs how data is managed, error correction, garbage collection, and other essential functions.

- Capacitors: Some SSDs include capacitors or supercapacitors, often referred to as power loss protection or PLP, to provide a small amount of power in case of sudden power loss. This helps ensure data integrity during write operations.

- Thermal Solutions: Depending on the design and intended usage, SSD PCBs may include heat spreaders, heat sinks, or thermal pads to manage heat generated during operation.

- Encryption Hardware: In some SSDs, hardware-based encryption features are included on the PCB to provide data security and encryption capabilities.

- External Enclosure PCB: In the case of external SSDs or portable SSDs, there may be an additional PCB in the enclosure that connects to the main SSD PCB and provides the external interface (e.g., USB or Thunderbolt).

The SSD PCB is a critical component that determines the performance, reliability, and features of the SSD. Different SSD models may have varying PCB designs to cater to different applications, including consumer laptops, desktops, data centers, and industrial applications. When choosing or working with SSDs, it’s essential to consider the PCB’s specifications, including the type of NAND flash, controller, and interface, to ensure compatibility and meet specific performance requirements.

SSD PCB

Designing and producing SSD (Solid-State Drive) PCBs (Printed Circuit Boards) presents several challenges and complexities due to the need for precision, reliability, and performance optimization. Here are some of the key design and production difficulties associated with SSD PCBs:

1. Miniaturization: SSDs are known for their compact form factors, and designers strive to make them as small as possible. This requires densely packed components, tiny soldering, and precise manufacturing processes to fit all necessary components onto the PCB.

2. Signal Integrity: High-speed data transfer within SSDs demands meticulous attention to signal integrity. Designers must consider impedance matching, EMI (Electromagnetic Interference) shielding, and noise reduction techniques to maintain data integrity.

3. NAND Flash Management: The controller chip on the SSD PCB manages multiple NAND flash memory chips. Implementing efficient wear-leveling algorithms, error correction, and garbage collection strategies is challenging to ensure consistent performance and longevity.

4. Controller Complexity: SSD controller chips are highly complex, responsible for various tasks, including data management, error handling, encryption, and power management. Designing and integrating these controllers accurately is crucial.

5. Thermal Management: SSDs can generate heat during operation, which can affect performance and longevity. Effective heat dissipation solutions such as thermal pads, heat sinks, and efficient airflow must be designed into the PCB.

6. Power Efficiency: SSDs need to balance performance with power efficiency. This requires careful design of power management circuitry, including low-power states and advanced power-saving features.

7. Firmware Integration: The firmware embedded within the SSD controller chip must be tightly integrated with the PCB’s hardware. Firmware updates and optimization can be challenging.

8. Component Sourcing: Ensuring the availability of high-quality NAND flash memory chips and controller chips can be challenging, especially during periods of semiconductor shortages.

9. Testing and Quality Control: Rigorous testing and quality control processes are essential to identify and rectify defects. Comprehensive testing for functionality, data integrity, and reliability can be resource-intensive.

10. Data Security: If the SSD includes hardware-based encryption, secure key storage and management must be carefully integrated into the PCB design.

11. Interface Compatibility: The SSD PCB must be compatible with various interface standards such as SATA, NVMe, and M.2. Meeting these standards while optimizing performance can be challenging.

12. Regulatory Compliance: SSDs must comply with industry standards and regulations, including electromagnetic compatibility (EMC) and safety standards.

13. Cost Management: Balancing performance and cost can be challenging. SSDs often use high-quality materials and advanced manufacturing techniques, which can drive up production costs.

14. Production Scaling: Scaling up production while maintaining consistency and quality can be difficult, especially for SSDs used in data center applications.

15. Environmental Considerations: Meeting environmental regulations and designing for sustainability are increasingly important. Materials selection and responsible disposal are considerations in PCB design.

To address these difficulties, SSD manufacturers employ highly skilled design and engineering teams, advanced CAD (Computer-Aided Design) software, simulation tools, and rigorous quality control processes. Additionally, ongoing research and development in NAND flash technology and SSD controllers help mitigate some of these challenges and drive innovation in the SSD industry.

Our company specializes in producing SSD PCB, and Kingspec is one of our SSD PCB customers.