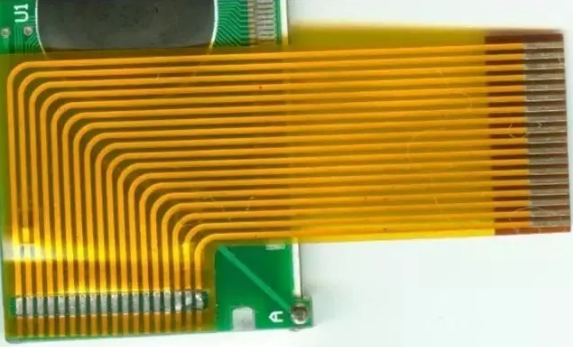

Flexible printed circuit board (FPCB) is a popular type of PCB, which is designed to meet the needs of flexible electronic circuits. Flexible circuit boards are the fastest alternative to traditional wiring harness because they are easy to shape to suit a variety of complex circuit designs. In addition, these boards provide design freedom while maintaining their performance and density. The performance of flexible PCB completely depends on the main materials. Choosing the best material is very important for the success of flexible PCB manufacturing. There are many kinds of materials, and they can meet the needs of modern design applications. This article will guide you to identify different aspects of the materials used in flexible circuit board manufacturing.

Types of flexible core or substrate materials used in flexible circuit board manufacturing.

The core material of flexible circuit board is made of adhesive and non-adhesive material. Both provide a range of polyimide core thickness.

- Adhesive based flexible materials: adhesive based materials are the main body of flexible circuit materials, which are usually used in the design of single-sided and double-sided circuit boards. As the name suggests, they use epoxy or acrylic based adhesives to glue copper to the flexible core. Adhesive based flexible materials have a wide range of advantages, including higher copper peel strength and lower material cost.

- Non viscous flexible material: this flexible core material is made by sputtering copper on the dielectric film or casting dielectric on copper. They are usually used when the design is a flexible structure with rigid or higher floors. In both cases, the non viscous flexible core provides superior quality and reliability. For some reasons, non viscous materials are widely used. One of the main advantages of this material is the absence of an adhesive layer, which leads to a flexible and thin structure. Other benefits of non viscous flexible materials include smaller possible minimum bending radius, higher potential temperature rating, etc.

Conductor materials used in flexible circuit board manufacturing

The use of thin, fine-grained, low profile copper foil can achieve a high level of flexible circuit board manufacturing. There are two main types of bendable material configurations for copper foil: ED and RA. Both binder base and non binder start from ed copper; however, during the RA process, the grain structure changes from vertical ed to horizontal RA copper.

In addition to the relatively low cost, ed copper foil is very popular in the market. RA foil is very expensive but has improved bending ability. In addition, RA foil is the standard material required for dynamic bending applications.

Cladding and flexible solder resist materials for flexible circuit board manufacturing

The flexible printed circuit board is composed of an outer circuit, which is packaged with a flexible solder resist layer, a cover layer or a combination of the two.

Flex PCB manufacturer used to use adhesives to glue these layers, which reduced the reliability of the circuit board to a certain extent. To address these issues, most of them now prefer overlay due to improved reliability and flexibility. Cover lay is characterized by a solid layer of polyimide with an acrylic or epoxy adhesive. Similarly, flexible solder mask is the preferred material for high-density SMT components used in rigid component areas. A good design habit is to use solder mask at the same time in the component area and cover at the same time in the flexible area to make full use of its function.

Over the years, flexible circuit boards have gained great popularity, and large-scale applications of complex circuits have been found. Choosing the right

flexible PCB material is very important, because it will not only affect the performance of the circuit board, but also affect the overall cost of the circuit board.