What is three proofing paint?

Three proofing paint is a kind of coating with special formula, which is used to protect circuit board and related equipment from environmental erosion. The three-proofing paint has good resistance to high and low temperature; after curing, it forms a transparent protective film, which has superior insulation, moisture-proof, anti-leakage, shockproof, dust-proof, anti-corrosion, anti-aging, corona resistance and other properties.

In real conditions, such as chemical, vibration, high dust, salt fog, humidity and high temperature environment, the circuit board may produce corrosion, softening, deformation, mildew and other problems, resulting in circuit board failure.

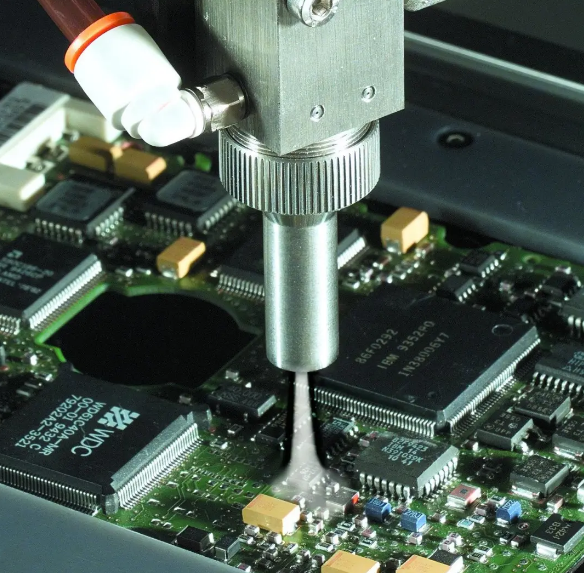

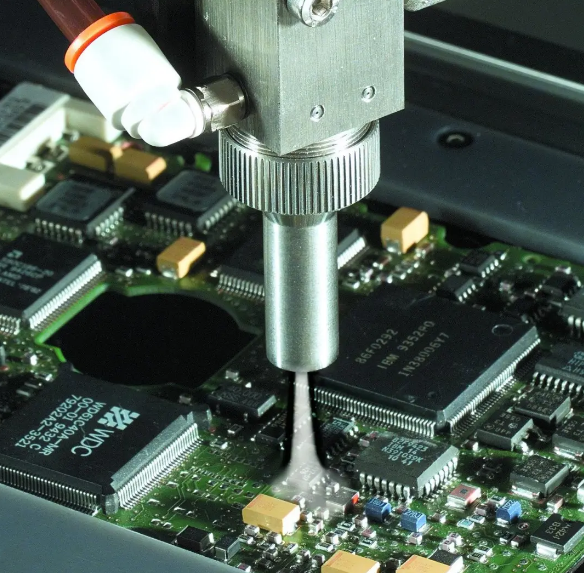

The three proofing paint is applied on the surface of the circuit board to form a layer of three proofing protective film (three proofing refers to moisture-proof, salt spray proof and mildew proof).

In the case of chemical substances (such as fuel, coolant, etc.), vibration, moisture, salt spray, humidity and high temperature, the circuit board without the three-proofing paint may be corroded, mold growth and short circuit, resulting in circuit failure. The use of the three-proofing paint during

PCB assembly can protect the circuit from damage, so as to improve the reliability of

PCB manufacturing, increase its safety factor and protect the circuit Its service life is verified.

In addition, because the three proofing paint can prevent leakage, it allows higher power and closer PCB spacing. Thus, the purpose of miniaturization of components can be satisfied.

Specifications and requirements of three proofing paint process

Painting requirements:

1. Painting thickness: the film thickness should be controlled within 0.05mm-0.15mm. The dry film thickness is 25um-40um.

2. Secondary coating: in order to ensure the thickness of products with high protection requirements, secondary coating can be carried out after the paint film is cured (determine whether to carry out secondary coating according to the demand).

3. Inspection and repair: visually check whether the coated circuit board meets the quality requirements, and repair the problem. For example, if the pins and other protection areas are stained with three proofing paint, they can be cleaned with tweezers clip degreasing cotton ball or clean cotton ball dipped in washing board water, and the normal paint film shall not be washed off during scrubbing.

4. Component replacement: after the paint film is cured, if you want to replace the component, you can operate as follows:

(1) Use electric ferrochrome to weld the components directly, and then use cotton cloth dipped in washing water to clean the material around the pad

(2) Welding substitute components

(3) Use a brush dipped in three proofing paint to coat the welding parts, and make the surface of the paint film dry and solidified

Operation requirements:

1. The workplace of three proofing paint is required to be dust-free, clean and free from dust. Good ventilation measures must be taken, and irrelevant personnel are forbidden to enter.

2. When operating, wear masks or gas masks, rubber gloves, chemical protective glasses and other protective equipment to avoid injury to the body.

3. After the completion of the work, the used tools shall be cleaned in time, and the containers with three proofing paints shall be sealed and tightly covered.

4. The anti-static measures should be taken for the circuit board, and the circuit board should not be overlapped. During the coating process, the circuit board should be placed horizontally.

Quality requirements:

1. The surface of circuit board shall be free of flowing paint and dripping. When painting with brush, attention shall be paid not to drip to the partially isolated part.

2. The coating shall be smooth, bright and uniform in thickness to protect the surface of pad, chip or conductor.

3. There shall be no bubble, pinhole, ripple, shrinkage hole, dust and other defects and foreign objects on the surface of paint layer and components, and there shall be no pulverization and peeling phenomenon. Attention: do not touch the paint film at will before the paint film is dry.

4. Components or areas with partial isolation shall not be coated with three proofing paint.

Parts and components that cannot be coated with three proofing paint.

1. Conventional uncoated components: Painted high-power radiator, heat sink, power resistance, high-power diode, cement resistance, dip switch, potentiometer (adjustable resistance), buzzer, battery base, fuse base, IC base, touch switch, relay and other types of socket, pin, wiring terminal,DB9, plug-in or chip mounted LED (non indicating function), digital switch Pipe, ground screw hole.

2. Parts and components that are not allowed to use three proofing paint according to the drawing.

3. According to the regulations in the catalogue of non three proofing components (areas), the components that are not allowed to use three proofing paint.

If the conventional uncoated components specified in the regulations need to be coated, the R & D department can specify the requirements or the drawings to carry out three proofing coating.

Matters needing attention in spraying process of three proofing paint

1. PCBA must be provided with process edge and its width should not be less than 5mm, so as to be convenient for running on the machine.

2. The maximum length and width of PCBA board is 410 * 410mm and the minimum is 10 * 10mm.

3. The maximum height of

PCBA mounted components is 80mm.

4. The minimum distance between spraying area and non spraying area of PCBA is 3mm.

5. Thorough cleaning can ensure that the corrosive residues are completely removed, and make the three proofing paint adhere to the circuit board surface well. The paint thickness should be between 0.1-0.3mm. Drying conditions: 60 ° C, 10-20 minutes.

6. In the process of spraying, some components are not allowed to be sprayed, such as high-power components with cooling surface or radiator, power resistance, power diode, cement resistance, dial switch, adjustable resistance, buzzer, battery base, safety seat (tube), IC base, touch switch, etc.