There is no doubt that printed circuit board (PCB) is a milestone tool in human technology. Why? This is because it is hidden in every electronic device today.

Like other great inventions in history, PCB is also gradually mature with the progress of the historical wheel. Up to now, it has a history of 130 years. It is the most beautiful scenery in the wheel of industrial revolution.

PCB has become a means to optimize the generation process of electronic equipment. Once upon a time, those electronic devices made by hand have to be replaced by PCB, which is because more functions will be integrated into the circuit board! Here are ten interesting facts about PCB:

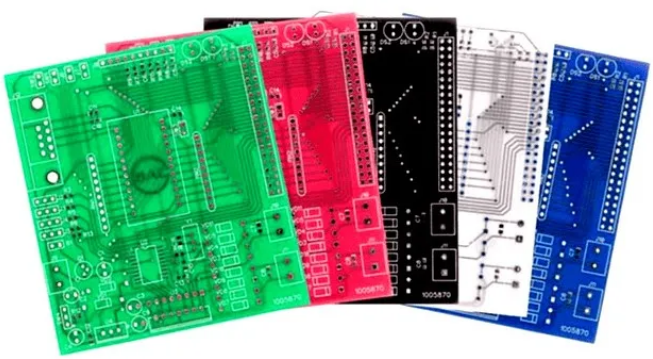

Colour

Even for those who don’t know what PCB is, they generally know what PCB looks like. They at least seem to give people a traditional style, that is, its green color.

This green is actually the transparent color of solder mask glass paint. The main function of solder mask is to protect the covered circuit from moisture and dust.

As for why the solder mask chooses green, the main reason is considered that green is the military protection standard. PCB in military equipment is the first to use solder mask to protect the reliability of the circuit in the field, and green is the natural protection color in the army.

Some people think that the epoxy resin used in the original solder mask paint was green in color itself, so it has been used today.

Now the color of solder mask is various, including black, red, yellow and so on. After all, green is not the industrial standard.

Who invented the PCB first?

If you ask who invented printing, this honor goes to Bi Sheng during the Northern Song Dynasty in China.

But the earliest printed circuit boards need to be traced back to the Austrian engineer Charles Ducas, who proposed in 1920 the concept of using ink to conduct electricity (printing brass wires on the backplane).

With the help of electroplating technology, he made wires directly on the surface of insulators, and made

PCB prototypes. At first, the metal wires on the circuit board were brass, an alloy of copper and zinc.

This subversive invention eliminated the complex wiring process of electronic circuits and ensured the reliability of circuit performance. This technology did not enter into practical application stage until the end of World War II.

Legend

There are also a lot of white marks on green circuit boards. For many years, people have not understood why these white printed marks are called “silkscreen layer”. They are mainly used to identify the information of components on the circuit board and other contents related to the circuit board.

This information was first printed on the circuit board by silkscreen printing, so it is called silkscreen layer. Now it is completed by special inkjet printer, which can help circuit engineers to check whether there is a fault in the circuit board.

Electronic components

The function of printed circuit board is mainly achieved by effectively connecting the components according to the schematic diagram. Each component has its own unique function, even if the two devices close to each other on the circuit board may be very different.

The types of devices basically include resistors, diodes, transistors, capacitors, relays, batteries, transformers, and many others (such as fuses, inductors, potentiometers, etc.).

Everywhere

It’s no exaggeration to say that PCB is everywhere, from computers to digital clocks, from microwave ovens to TV sets and stereo sound systems.

As long as electronic items and equipment, more than 99% of them contain PCB, so we may take it for granted that without PCB, any electronic equipment will not work.

NASA

In many NASA projects, some groundbreaking technologies have been used. In the 1960s, NASA used PCB on Apollo 11 rocket, because PCB based electronic devices are light in weight and low in power consumption.

That was the greatest moment of mankind, the first time to send an astronaut to the moon, which was attributed to PCB.

Surface mount technology (SMT)

SMT makes PCB into the modernization. Compared with the previous Jack installation method, this SMT uses special glue to paste the device on the PCB, and then connects the components and the circuit board through special reflow soldering.

Rapid prototyping PCB

In the process of local experiment, bread PCB, hole PCB and other general circuit boards can be used for testing.

With the increase of surface packaging components, there are also new rapid PCB forming technologies, such as heat transfer PCB,3D printing multilayer circuit board, etc.

Flexible PCB

PCBs are not all straight and rigid, but there are many flexible PCBs working in many compact electronic devices. They often constitute the application circuits in many movable joints or multi-layer stereoscopic circuits.

The largest PCB in the world

The largest PCB in the world comes from Johnson electronics, a multi-layer flexible PCB used in unmanned solar aircraft.

It is about 28 meters long. It is made of flexible polyimide. The circuit board has better heat dissipation and higher conductivity density.