FPC (Flexible Printed Circuit Board) connectors and BTB (Board-to-Board) connectors are both used to establish electrical connections between PCBs or other electronic components, but they have several key differences:

- Flexibility vs. Rigid Connection:

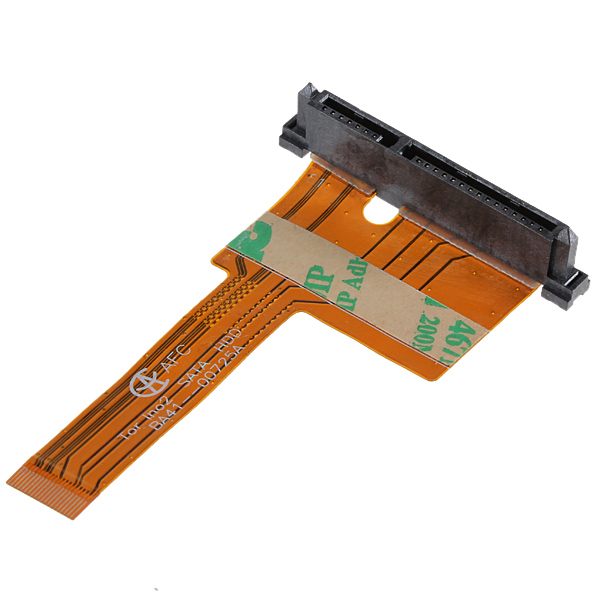

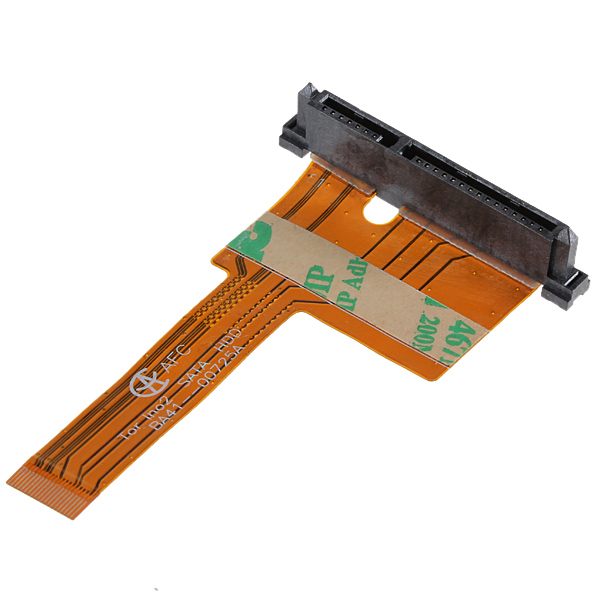

- FPC Connector: FPC connectors are designed for flexible circuits and are used to connect flexible printed circuit boards. They are ideal for applications where the connection needs to bend or flex, such as in laptops, smartphones, and cameras.

- BTB Connector: BTB connectors, on the other hand, are rigid and used to connect standard printed circuit boards. They are intended for applications where a solid and stationary connection is required, such as in desktop computers or industrial equipment.

- Form Factor and Design:

- FPC Connector: FPC connectors have a flat, low-profile design with a lightweight and thin form factor. They are typically designed to accommodate the thin, flexible nature of FPCs.

- BTB Connector: BTB connectors are more robust and come in various sizes and configurations to match the specific requirements of the PCB or application. They may have different form factors, including mezzanine, coplanar, or vertical configurations.

- Termination Method:

- FPC Connector: FPC connectors typically use a clamping or compression mechanism to grip the flexible PCB in place, ensuring electrical contact. These connectors are designed to be mated and unmated multiple times without damaging the FPC.

- BTB Connector: BTB connectors often use pin and receptacle or socket contacts that align with matching connectors on the opposing PCB. The connection is more secure and stable but may not be intended for frequent disconnection.

- Application and Environment:

- FPC Connector: FPC connectors are commonly found in compact, portable devices where space and weight are critical factors. They are also used in applications where the connection needs to flex, such as in moving parts of a device.

- BTB Connector: BTB connectors are typically used in applications that require a stable and permanent connection between PCBs, such as in industrial equipment, servers, or fixed electronic systems.

- Durability:

- FPC Connector: FPC connectors are designed for flexibility and bending. They are durable but not intended for repeated or high-stress bending.

- BTB Connector: BTB connectors are built for more static or stationary connections and are generally more robust and durable in fixed installations.

- Cost:

- FPC Connector: FPC connectors are often more cost-effective for smaller, lightweight, and portable electronic devices.

- BTB Connector: BTB connectors may be more expensive due to their larger size, complexity, and durability features.

In summary, the primary difference between FPC connectors and BTB connectors lies in their flexibility and rigidity. FPC connectors are designed for flexible circuit applications, while BTB connectors are intended for standard, rigid PCB connections. The choice between them depends on the specific needs of the electronic system, including flexibility requirements, form factor, and environmental conditions.