A Printed Circuit Board, commonly known as a PCB, is a critical element in modern electronics. It serves as a foundation for electrical components and connections, enabling the assembly of complex electronic circuits. This article provides an in-depth look at the history, types, and significance of PCBs in the world of technology.

The concept of printed circuits can be traced back to the late 19th century, but PCBs as we know them today have undergone significant evolution.

1. Early Developments: Before PCBs, electronic circuits were constructed using point-to-point wiring, which was cumbersome and prone to errors. In the early 20th century, researchers began experimenting with various techniques to simplify circuit assembly.

2. The Birth of PCBs: Paul Eisler, an Austrian engineer, is credited with inventing the modern PCB in 1936. His invention had applications in radio technology, which was becoming increasingly popular at the time. During World War II, PCBs gained importance in military applications.

3. Advancements in Materials: Over the years, PCB materials have evolved from simple bakelite to more advanced substrates, such as epoxy, fiberglass, and polyimide. These materials offer improved electrical properties, mechanical strength, and thermal resistance.

4. Surface Mount Technology (SMT): The introduction of SMT in the 1980s revolutionized PCB assembly. It enabled smaller and more densely populated boards, contributing to the miniaturization of electronic devices.

PCBs come in various types, each designed to suit specific applications and requirements:

1. Single-Sided PCBs: These have a conductive layer on one side and are commonly used in simple, low-cost applications.

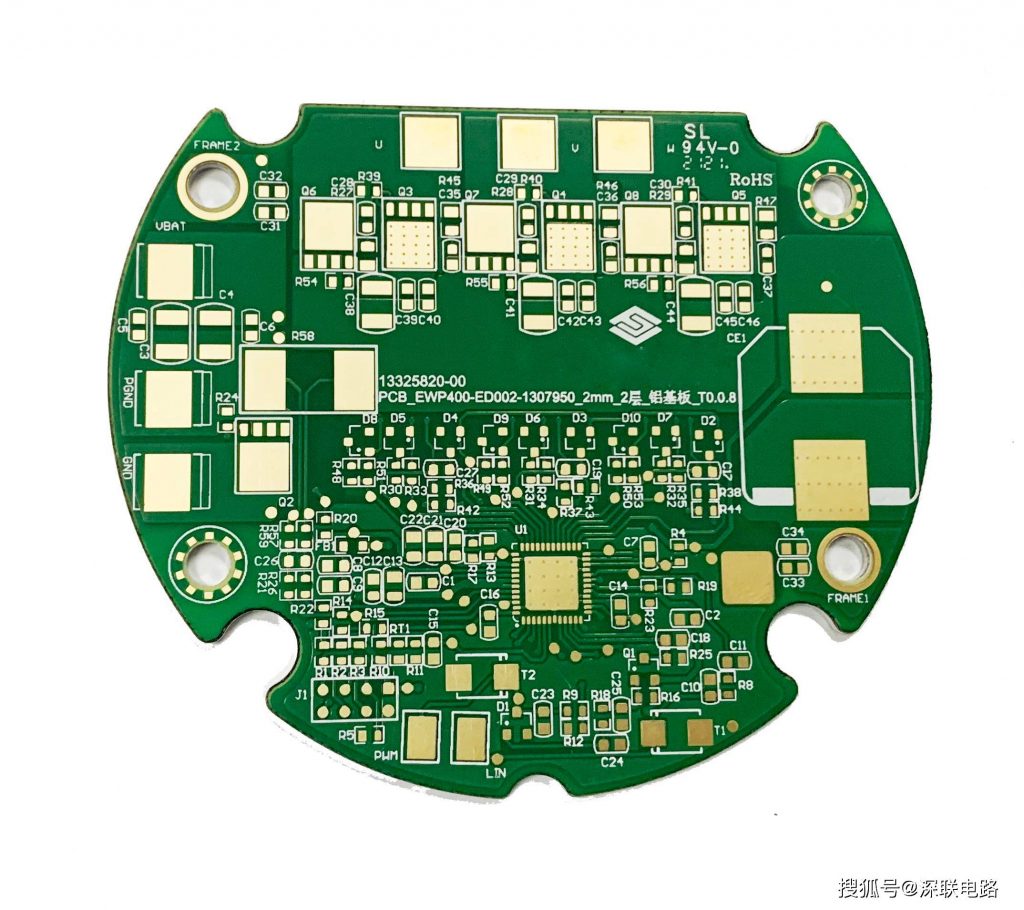

2. Double-Sided PCBs: These have conductive layers on both sides, connected by plated through-holes. They are widely used in consumer electronics and industrial applications.

3. Multi-Layer PCBs: These consist of three or more conductive layers separated by insulating material. Multi-layer PCBs are used in complex, high-performance devices like computers and smartphones.

4. Rigid PCBs: These are the traditional, inflexible PCBs used in most electronics.

5. Flexible PCBs (Flex PCBs): Made from flexible materials like polyimide, they are ideal for applications where the board must bend or conform to a specific shape. Common in wearables and medical devices.

6. Rigid-Flex PCBs: A hybrid of rigid and flexible PCBs, these combine the benefits of both, making them suitable for intricate, space-constrained designs.

7. High-Frequency PCBs: Designed for applications with stringent signal integrity requirements, such as in the telecommunications and aerospace industries.

PCBs are integral to the functioning of almost all electronic devices. Here’s why they are so significant:

1. Simplified Assembly: PCBs simplify the assembly process, making it faster, more reliable, and cost-effective.

2. Compact Design: They allow for the miniaturization of electronic devices, making them smaller and more portable.

3. Improved Signal Integrity: PCBs offer controlled impedance, which is crucial for high-frequency applications.

4. Increased Reliability: PCBs provide a stable platform for component placement, reducing the risk of loose connections or errors.

5. Economic Benefits: Mass production of PCBs lowers manufacturing costs and contributes to the affordability of electronics.

Printed Circuit Boards have come a long way from their inception in the early 20th century. Their evolution, from simple single-sided boards to complex multi-layer and flexible designs, has played a pivotal role in shaping the modern electronics industry. With their capacity to simplify assembly, reduce size, and enhance reliability, PCBs are the backbone of our interconnected world.

PCBSky is one of China custom PCB merchants and a Shenzhen PCB manufacturer. Welcome to know.