FPC stands for Flexible PCB. It is a type of printed circuit board (PCB) that is designed to be flexible and can conform to various shapes and contours. FPCs are also known as flexible PCBs or flex circuits. They are used in a wide range of electronic devices and applications where traditional rigid PCBs are not suitable due to space constraints or the need for flexibility.

Key characteristics and features of FPCs include:

FPCs find application in various industries, including consumer electronics, automotive, medical devices, aerospace, and more. Common uses include flexible displays, wearables, automotive sensors, and medical devices. The flexibility of FPCs allows them to adapt to the specific needs of these industries, enabling innovative and space-efficient designs.

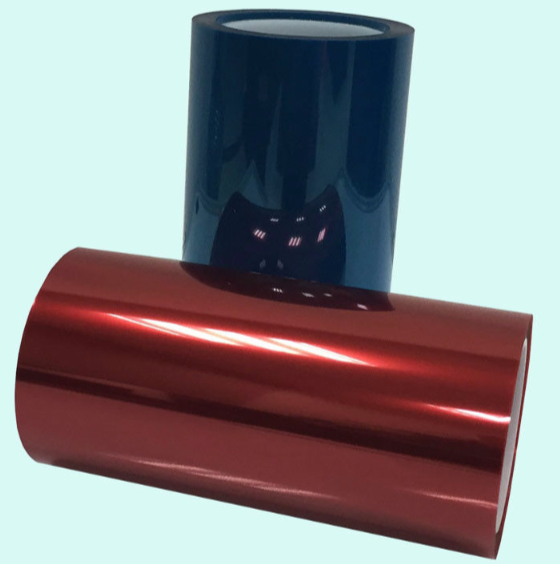

FPC release film is composed of super transparent polyester film (PET) coated with special silica gel, then bonded with pet release film, and then bonded with pet protective film on the hardened surface. FPC thin plate load-bearing film is a kind of functional film used when the thickness of FPC substrate is thin. It has many choices, such as ordinary load-bearing film and high-temperature bearing film, which is suitable for all kinds of flexible PCB substrates.

FPC release film is mainly used in flexible circuit board, with the characteristics of high density, light weight and thin thickness. It is mainly used in mobile phones, notebook computers, PDA, digital cameras, LCM and many other products. FPC soft printed circuit is a kind of highly reliable and excellent flexible printed circuit made of Polyimide or polyester film.