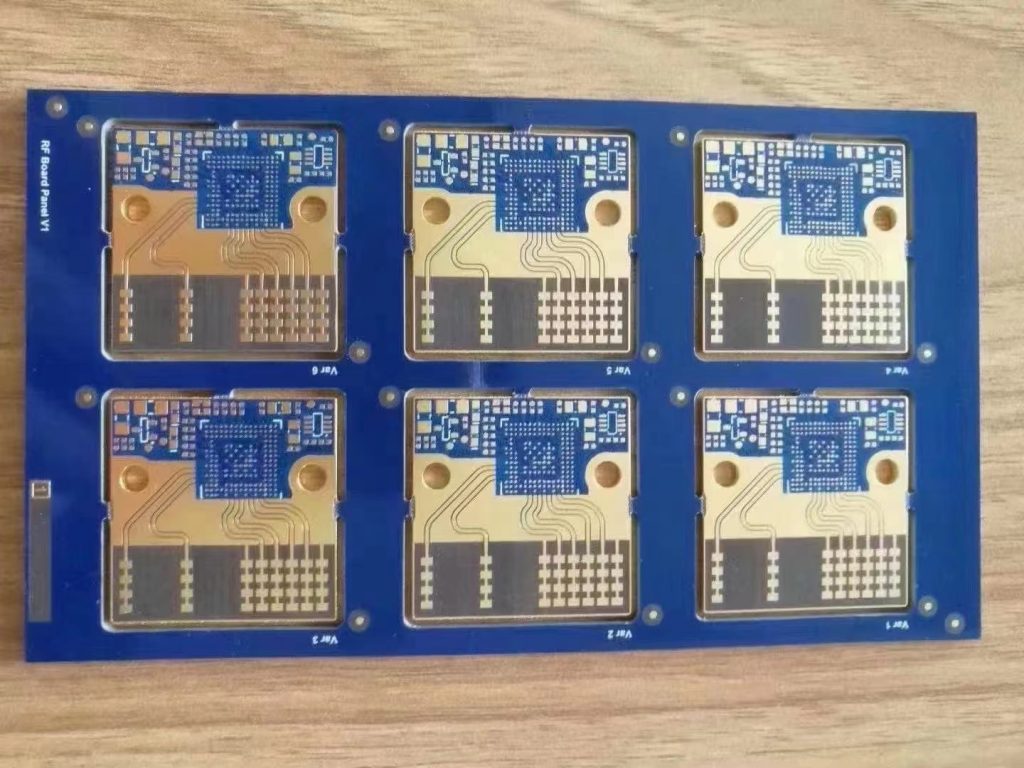

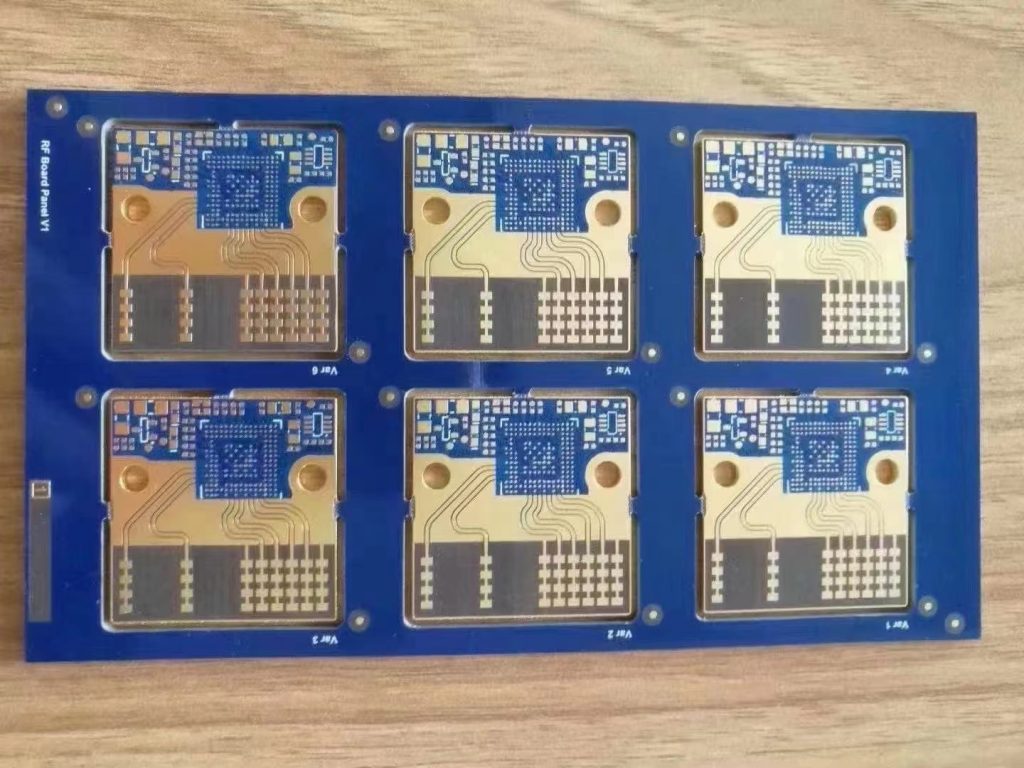

Both

RO4350b PCB and

RO4835 PCB belong to Rogers 4000 series PCB and belong to civil products. Ro4000 series is a kind of laminated material of hydrocarbon resin and ceramic materials. It has the ability of compatible with FR4 mixed pressing, FR-4 processing technology and lead-free welding process. It ensures that PCB processing plant only needs to have lower processing capacity and reduce PCB processing cost, while its low loss (DF) is 0 0037@10GHz ??The temperature stability of dielectric constant is better (50 ppm / °) C@-50 °C to Compared with the traditional PTFE material, the heat treatment capacity is better (heat dissipation coefficient is 0.6w/m / ° K), and the z-axis thermal expansion coefficient (31 ppm / ° C) improves the reliability of through-hole, which can ensure the excellent electrical performance of radar front-end and antenna at 24GHz. Moreover, it belongs to UL 94V-0 flame retardant material, which further contributes to the safety of radar system.

RO4350B and RO4835 are both high-frequency laminate materials commonly used for designing and fabricating radio frequency (RF) and microwave printed circuit boards (PCBs). While they share some similarities, they also have notable differences. Here are the key distinctions between RO4350B and RO4835 PCB materials:

- Dielectric Constant (Dk) and Loss Tangent (Df):

- RO4350B typically has a lower dielectric constant (Dk) of around 3.48, making it suitable for applications where maintaining consistent impedance is crucial.

- RO4835, on the other hand, has a slightly higher Dk, generally around 3.5, which can be advantageous for specific design requirements.

- Dissipation Factor (Df):

- RO4350B typically has a lower loss tangent (Df), which means it has lower signal loss at higher frequencies. This makes it suitable for applications demanding low signal loss and high performance.

- Cost:

- RO4350B is often considered a cost-effective choice for RF and microwave applications due to its lower dielectric constant and lower loss tangent. It provides good performance while being more budget friendly.

- Thermal Performance:

- RO4350B and RO4835 have similar thermal performance characteristics. Both materials can handle a wide temperature range without significant degradation.

- Applications:

- RO4350B is commonly used in applications where low loss and controlled impedance are critical, such as cellular base station antennas, satellite communication systems, and radar systems.

- RO4835 is often chosen for applications that require a slightly higher dielectric constant or specific design characteristics.

It’s essential to carefully consider your specific project requirements and performance needs when choosing between these materials. The decision may also depend on factors such as cost, availability, and the capabilities of your PCB fabrication partner. Additionally, the properties of these materials can vary by manufacturer, so it’s essential to check the datasheets and consult with your PCB supplier to make an informed choice based on your project’s needs.

Lots of customers come to buy Rogers PCB. We keep All types of Rogers material in stock, if you need any of them, welcome to contact us for the price and datasheet.